Are HMR boards the same as MDF boards? What's the difference?

2024-07-02 15:30

In modern home decoration and furniture manufacturing, the choice of panels is crucial. Two common board materials - high moisture-proof board (HMR board) and medium density fiber board (MDF board) often confuse consumers. Although they may look similar in appearance, there are actually significant differences in performance and application.

This article will delve into the characteristics, application scenarios and main differences between HMR boards and MDF boards to help consumers and industry practitioners better understand and choose these two boards.

Basic overview of HMR boards and MDF boards

What is HMR board?

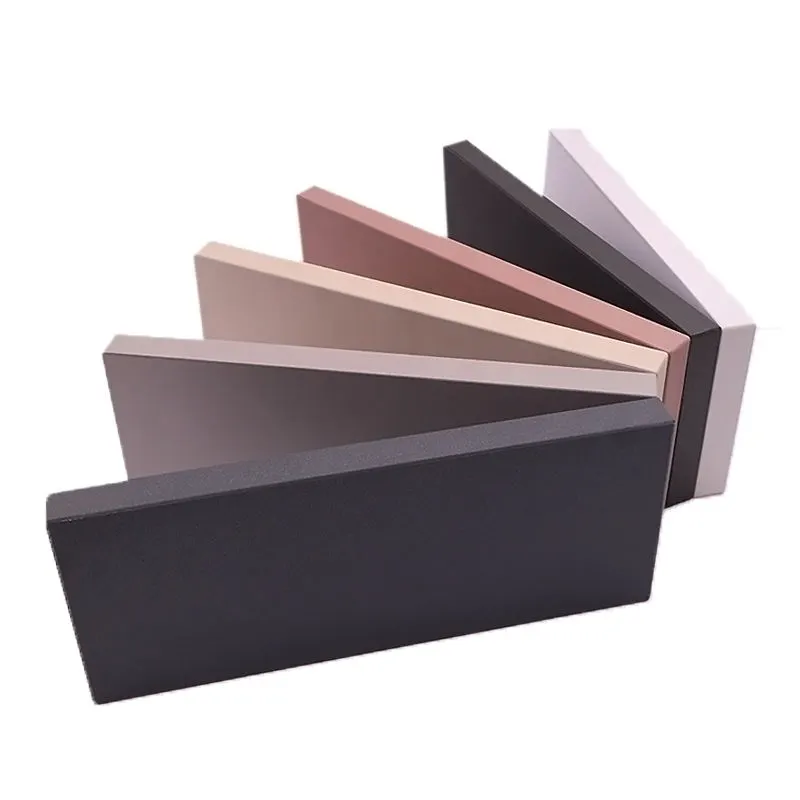

HMR (High Moisture Resistant) board is a fiberboard made by adding moisture-proof agent and special process, which has excellent moisture-proof performance. Its density is usually between 600-800kg/m³. The main feature of HMR board is its ability to maintain stability in high-humidity environments and is not prone to hygroscopic expansion and deformation. It is suitable for humid areas such as kitchens and bathrooms.

What is MDF board?

MDF (Medium Density Fiber) board is a medium density board made of wood fiber through a hot pressing process. The density is usually between 600-800kg/m³. MDF board has good flatness and processability, smooth surface, and is easy to undergo various surface treatments, such as spray painting, veneer, etc., and is widely used in furniture manufacturing and building interior decoration.

Similarities in performance between HMR boards and MDF boards

1. Source of materials:

The raw materials of HMR board and MDF board are wood fiber, which are made through similar hot pressing process. This gives them a somewhat similar texture and appearance.

2. Environmental performance:

Both types of boards use environmentally friendly adhesives during the production process. The amount of formaldehyde released is low, complying with environmental standards, and ensuring the health and safety of the living environment.

3. Processability:

Both HMR boards and MDF boards have good processability and can be used for cutting, drilling, engraving and other processing techniques to meet different design and production needs.

Differences in performance between HMR boards and MDF boards

1. Moisture-proof performance:

●HMR board: The distinctive feature of HMR board is its excellent moisture-proof performance. By adding moisture-proof agents and special treatments during the production process, HMR boards can remain stable in high-humidity environments and are not prone to hygroscopic expansion. This makes HMR panels ideal for humid environments such as kitchens and bathrooms.

●MDF board: In comparison, the moisture-proof performance of MDF board is weak. In high-humidity environments, MDF boards are prone to hygroscopic expansion and deformation, limiting their application in humid areas. Therefore, MDF boards are more suitable for dry environments, such as bedrooms, living rooms and other interior decorations.

2. Strength and hardness:

●HMR board: HMR board has moderate density and strength, and is suitable for applications that require moisture resistance but do not require extremely high strength. It is strong enough for everyday use, but will not perform as well as high-density boards in applications that require high strength.

●MDF board: The strength and hardness of MDF board are similar to HMR board, making it suitable for most furniture and decoration applications. However, due to its poor moisture-proof performance, it is not suitable for use in humid environments.

3. Surface treatment and decoration:

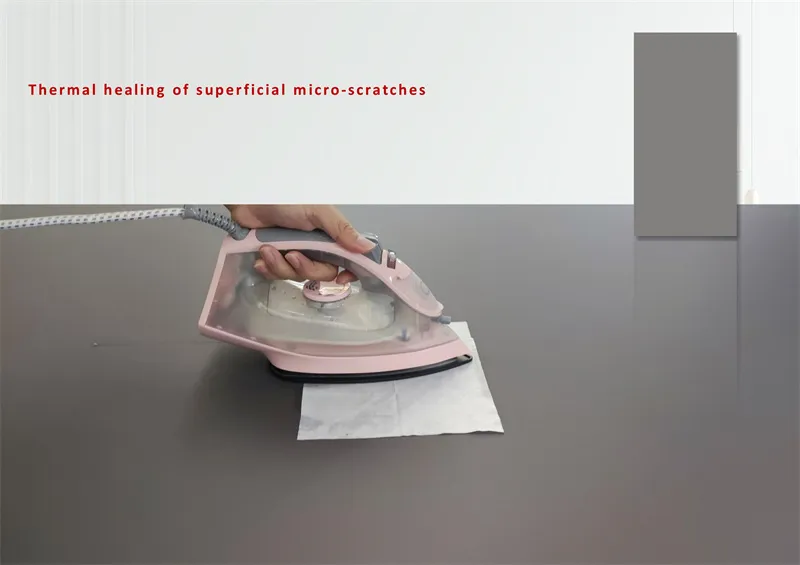

●HMR board: The surface of HMR board is smooth and flat, and it can be subjected to certain surface treatments, such as veneer and painting. However, its main advantage is its moisture-proof performance, and its decorative properties are not as diverse as MDF board.

●MDF board: MDF board has a smooth surface and is very suitable for various surface treatments, such as spray painting, veneer, lamination, etc. MDF boards are highly decorative, can meet a variety of design needs, and are widely used in furniture and interior decoration.

Comparison of application scenarios of HMR board and MDF board

1. Furniture manufacturing:

●HMR board: suitable for the manufacture of kitchen and bathroom furniture, such as cabinets, bathroom cabinets, etc. These furniture are used in high-humidity environments, and the moisture-proof performance of HMR boards can effectively prevent the boards from being deformed by moisture.

●MDF board: suitable for furniture manufacturing in dry environments such as bedrooms and living rooms, such as wardrobes, bookshelves, bedside tables, etc. The surface treatment effect of MDF board is good and can meet various decoration needs.

2. Building interior:

●HMR board: suitable for wall and ceiling decoration in kitchens and bathrooms, and can maintain good performance in humid environments.

●MDF board: suitable for wall and ceiling decoration in indoor dry environments. Its surface treatment effect is good and it can provide rich decorative effects.

3. Floor base material:

●HMR board: suitable for floor base materials that require moisture-proof properties, such as kitchen and bathroom floor foundations. HMR board can effectively prevent the floor from swelling and deformation due to moisture.

●MDF board: Due to poor moisture-proof performance, it is not suitable as a floor base material in humid environments. But in dry environments, MDF boards can be used as floor substrates, providing good flatness and stability.

Conclusion

As important materials in the modern home building materials market, HMR boards and MDF boards each have their own unique advantages and application scenarios. When consumers choose, they should consider comprehensively based on specific needs, budget and usage environment.

Whether you need kitchen and bathroom cabinets with excellent moisture-proof performance, or bedroom and living room furniture with good decorative effects, HMR boards and MDF boards can provide corresponding solutions.