How to laminate transparent PET film onto board well and avoiding bubbles, particles, and wavy patterns?

2023-06-30 04:00

How to laminate transparent PET film onto board well and avoiding bubbles, particles, and wavy patterns?

With the diversification of consumer demand, quickly meeting the different needs of consumers has become a new direction for industry development. The breakthrough in transparent highlight technology has given veneers a new look, bringing consumers a unique sense of luxury and modernity.

In the era of customized home furnishings, everyone has a pursuit. Home panels should meet various decorative effects, be waterproof, wear-resistant, corrosion-resistant, and have a sense of beauty, texture, and space. Veneer decoration is a "cosmetic needle" for panel furniture, which can quickly meet the needs of different consumers.

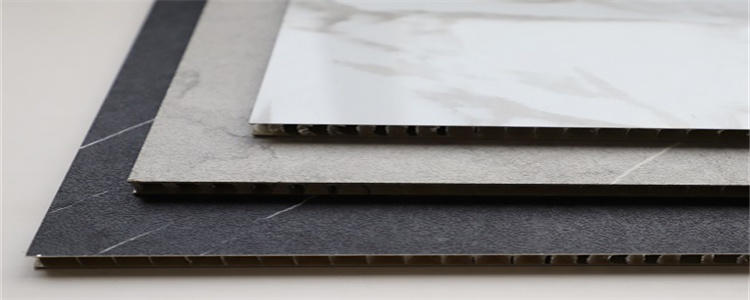

Recently, at major exhibitions, home exhibitions, and construction exhibitions, there is a type of decorative board that stands out particularly. Furniture, wall panels, doors, etc. made of this type of board often have bright colors and give people a strong visual impact. It is a transparent PET film decorative material.

The production of this type of board relies on thin film flat bonding technology, commonly used films include PVC, PP, PET, PETG, etc., which can be applied to density boards, multi-layer boards, aluminum boards, calcium silicate boards, and other boards, with rich and colorful effects. What are the key points to sticking a transparent panel well? In addition to requiring high-quality transparent pet film, supporting flat pasting equipment is also required.

01 What is the Difficulty of Film Flat Stick Technology

The transparent film flat pasting technology involves multiple processes such as dust removal, adhesive application, solvent evaporation, and film flat pasting. Each link is related to the quality of the veneer board. Especially for the decoration of transparent pet film, the problems are even more challenging. Specifically, there are the following difficulties:

① The surface is prone to bubbles, orange peel, wire drawing, dust, etc., making it difficult to control the effect;

② High material prices and costs;

③ Paste transparent pet film, high gloss defect rate;

④ The difficulty in using the equipment is high, and there is a shortage of technical personnel.

02 Innovative Film Flat Stick Technology and Equipment

The special precision Hot-melt adhesive coating machine is used, which is specially used for plane plate veneer and multi-layer plate bonding; Apply PUR adhesive flat to PP, PVC, PET, PETG and other roll sheets; Suitable for the production of high gloss veneers, as well as the bonding of cabinet and furniture door panels, honeycomb panels, and foam panels; It is widely used in industries such as building materials and decoration.

What are the characteristics and advantages of the technology and equipment of the PUR flat sticker production line?

02-1 Laminate pet film boards with high quality

(1) No Bubbles

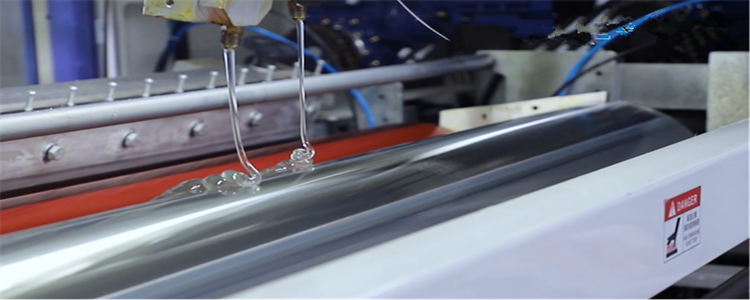

The adhesive coating system can achieve a smooth and delicate surface like a mirror when scraping; The rolling system can evenly roll and effectively solve the problem of bubbles.

(2) No particles

Four major dust collection systems, including double-sided dust removal, high-temperature dust removal, plate dust collection, and membrane dust collection, effectively solve the problem of dust on the board surface by comprehensively and from multiple angles.

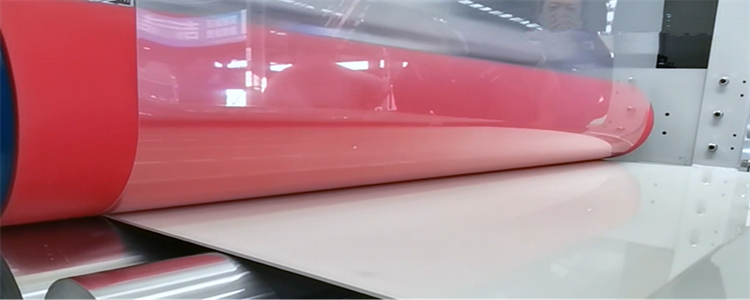

(3) No wave pattern

By combining the principles of mechanics, the tension and structure of the film are optimized, and the surface effect is free from wavy patterns and smooth like a mirror. The PET transparent film produced by Zhihua Group is controlled by high-end precision and advanced production equipment, and every meter of film produced perfectly interprets this effect.

02-2 Laminate thinner film with lower cost

Breaking through industry bottlenecks, transparent high gloss PETG film veneer has been reduced from 25 commonly used threads in the industry to 18 thinner threads, resulting in lower costs.

02-3 The finished product rate is higher laminating transparent pet film

Transparent PETG products, continuously sticking 100 large boards without pressure, with a daily production capacity of about 800 large boards.

02-4 Strong competitiveness of laminating pet film products

(1) Large selection space

Multiple finished effects meet personalized needs, making styles rich and diverse.

(2) Strong market competitiveness

Upgrading product value, upgrading product appearance, and using better substrates to win can stand out in markets with severe homogenization.

03 Technical Guidelines for Common Film Flat Sticking

What is the difference in the use of tape adhesive, UV shadowless adhesive, and PUR adhesive?

The back adhesive process involves coating UV, covering pre curing, and then shaping and curing.

Over time, the gloss of the shadowless adhesive becomes dim, and there may be cracks. The cut edges may burst, and the adhesive strength and durability are slightly poor. To completely avoid the above problems, the cost is relatively high.

The use of PUR adhesive has good quick drying effect and adhesion.

04 As for the selection of transparent PET film, whether a good decorative pet film laminate plate can be pasted well or not, it is particularly critical to select transparent PET film with excellent cost performance .

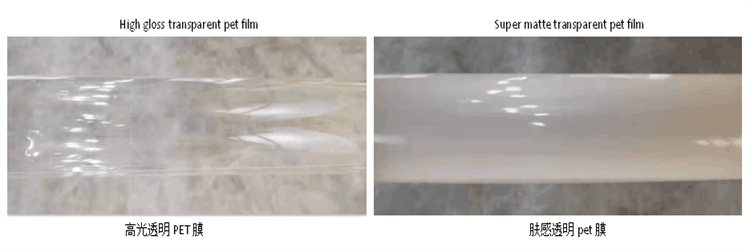

Zhihua Group has the first high-end production equipment for extruded decorative film materials jointly developed with European SML in Asia, as well as 200 meter long surface treatment excimer coating process coating and wiring from Europe, 160 meter long pure European imported hardening production equipment, as well as the first domestically imported EB electron beam curing production equipment, pure imported production equipment and production processes, The perfect solution to the problem of insufficient surface smoothness in producing high-quality PET transparent film/PET high gloss solid color film, and the introduction of EB electronic curing equipment and technology to create a high-quality roll of good film. To produce a good transparent decorative panel, Zhihua Group's honor produced high gloss transparent pet film is your best choice. At the same time, our group's excimer process coating line perfectly produces anti fingerprint, wear-resistant, scratch resistant, and super dull transparent pet film, allowing you to synchronously promote high gloss and matte panels, allowing consumers to have more diverse choices. The available sizes for pet transparency are: 1260 * 0.18MM, 1260 * 0.25MM

05 Conclusion

With the diversification of consumer demand, quickly meeting the different needs of consumers has become a new direction for industry development. The breakthrough in transparent highlight technology has given veneers a new look, bringing consumers a unique sense of luxury and modernity. Through the PUR lamination production line, the high-quality transparent PET film laminating onto board , Zhihua Group enriches and diversifies product styles, and can quickly and efficiently meet consumers' needs for high-quality life. The large home customization industry is approaching a new peak!