Production process and product effect of 3 types matte finish boards

2023-04-26 15:00

Production process and product effect of 3 types matte finish boards!

With the development of the furniture industry, the skin matte board (SMB) used on the surface of furniture is gradually being favored by the Chinese home market for its delicate and silky touch like baby skin, as well as the extremely matte, soft and elegant appearance of the board surface, becoming a high-end design material.

There are three main production methods for processing matte finish boards:

One is to use flat bonding line to do super matte board, which uses PUR laminating line to paste the EB matte film onto fiberboard, particle board and plywood; At present, Zhihua Group has the first most advanced extrusion production equipment and EB coating process equipment in Asia, and the film/sheet produced is second to none in terms of cost-effectiveness;

The second is to use film pressing line to make skin matte board. By using the film pouring process and UV curing method, the texture and effect of the PVC skin sensitive film are pressed and printed on the melamine board. The pressed film does not stay on the board, so the degree of membrane recycling is high;

The third is to use excimer lamp technology to make skin matte boards, coating paint on melamine boards, and then using excimer lamp technology to facilitate automatic arrangement of paint molecules in an inert gas environment. Paint coating is used without film consumption.

In response to the rapid development of skin matte boards, some domestic equipment manufacturers have successively developed professional equipment to ensure the surface effect of skin matte boards (such as the EB coating process production line of Zhihua Group), but their coating process plan mainly stays on a flat surface for conventional skin matte treatment, and the matte degree of surface effect is gradually unable to meet people's needs.

The high quality requirements for home decoration have led to a significant increase in the application of panels with three-dimensional patterns or shapes, while existing flat matte machines cannot perform matte treatment on three-dimensional surfaces.

01 Three production processes for producing matte board

To make a skin matte board with flat thread, the first step is to perform double-sided dust removal treatment on the surface of the workpiece to prevent raised dust particles from appearing on the finished board surface; Then preheat the board to reduce the temperature difference between PUR adhesive and the board when applied to the surface; After the preheating of the board is completed, apply PUR adhesive and scrape the adhesive flat. At the same time, perform insulation treatment on PUR adhesive; Then stick the EB film/sheet onto the board (currently, the EB film/sheet produced by Zhihua Group Dayi is popular among consumers, and many board/furniture factories/customization factories choose the EB film/sheet produced by Zhihua Group), and enter the four roller rolling press for pressing and pasting; Finally, according to the process requirements, the material is discharged through processes such as beveling, trimming, and film covering protection.

To make a skin matte board with film pressing line, the first step is to remove dust from the board surface, and then roll a layer of UV paint onto the board surface before entering the molding machine; The pressing wheel of the molding machine presses the PVC skin feeling film onto the UV paint on the board surface. While pressing, it can also level the paint surface with the film attached, and the UV lamp solidifies the surface. Then, the PVC skin feeling film attached to the paint surface is collected by the release roller at the outlet of the molding machine, leaving only the UV oil paint coating on the board surface (the skin feeling effect of the paint surface is the effect of the film surface); Subsequently, complete curing is carried out using a dual lamp or triple lamp UV dryer; Finally, cover the protective film and cut the material.

Excimer is a spontaneous emission light source that converts the inert gas, halogen, or inert gas halide filled in the lamp tube into an excited dimer R2 *, X2 *, or RX *, and then emits incoherent ultraviolet (UV with a wavelength between 200nm and 400nm) and vacuum ultraviolet (VUV with a wavelength between 100nm and 200nm) spectra. The photon energy of vacuum ultraviolet radiation is above 6 eV, which is higher than the bond energy of most chemical bond. It has the function of stimulating chemical reactions at room temperature and changing the surface structure and properties of materials, so as to form an ultra matte surface of paint.

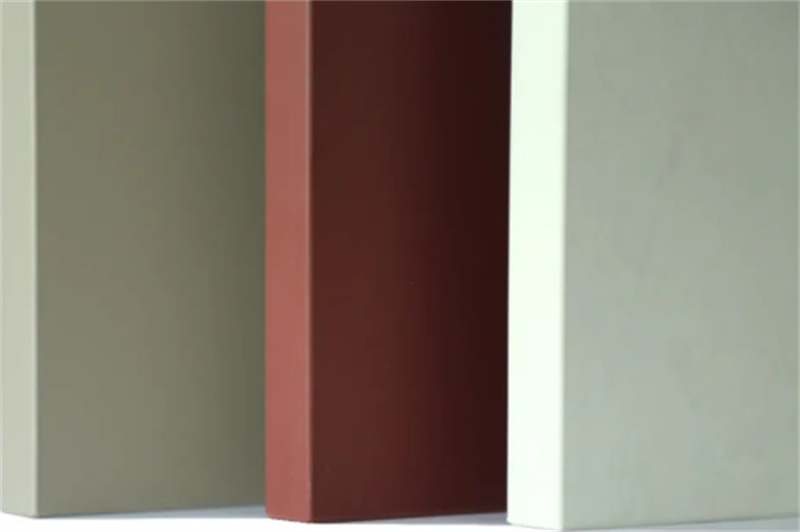

02 Product effects of three types of matte finish boards

In terms of product effect, the EB process coating film applied flat to the board has excellent scratch resistance, fingerprint resistance, and yellowing resistance. In terms of glossiness, flatness, gloss uniformity, and production line speed, it has obvious advantages compared to excimer skin matte board and film pressure skin matte board.

Flat skin matte board: Effect type: By applying EB matte film on the board, it completely avoids the phenomenon of poor surface smoothness caused by uneven flatness of the board. The effect is realistic, and the color is pure and natural; Long lasting effect: Due to the use of EB process coating and the most advanced production process coating in the market, it can anti yellowing for over 10 years; The effect of the film: scratch resistance, chemical resistance, fingerprint resistance, oil resistance, stain resistance , easy cleaning, and environmental protection. Glossiness/°: 1-3; Gloss uniformity: very good; Production environment: It is recommended to produce in a dust-free production environment; Working speed/(m/min): 8-15.

Membrane pressure skin hoarse board: Effect type: Single skin sensation effect; Effect duration: The skin feels thin, and the effect disappears after a few months; Weak scratch resistance, fingerprint resistance, stain resistance, easy yellowing, similar to conventional paint; Glossiness/°: 4-5; Gloss uniformity: influenced by the quality of the film; Flaw points: Dust can produce bubble points; Working speed/(m/min): 8-10.

Excimer lamp skin matte board: Effect type: Multiple different effects; Duration of effect: Thick skin sensation layer, maintaining skin sensation effect for a long time; Good scratch resistance, fingerprint resistance, stain resistance, and resistance to yellowing; Glossiness/°: 2-4; Gloss uniformity: depends on whether the paint has cured completely; Flaw points: occasional bubbles; Working speed/(m/min): 10-50.