What is PET MDF board? What is PET?

2024-08-13 15:30

In the field of modern furniture manufacturing and interior decoration, various new materials emerge in an endless stream, and PET MDF board has quickly emerged due to its unique performance and environmental protection advantages. With people's pursuit of high-quality life and the improvement of environmental awareness, the application prospects of PET MDF board have attracted much attention.

So, what is PET MDF board? What is PET? This article will explore this topic in detail to help readers fully understand PET MDF board and its material characteristics.

What is PET MDF board?

PET MDF board is a new composite material with PET film on the surface of medium-density fiberboard (MDF). MDF board is mainly composed of wood fiber and resin, and is pressed by high temperature and high pressure. It has the advantages of uniform structure, flat surface and easy processing. PET film is a thin film material made of polyethylene terephthalate (PET) with excellent physical and chemical properties.

What are the material properties of PET?

PET is a high molecular polymer formed by the polymerization of terephthalic acid (PTA) and ethylene glycol (EG). It has excellent chemical resistance, heat resistance, mechanical strength and transparency, so it is widely used in food packaging, textiles, electronic products and other fields. Applying PET to the surface treatment of MDF boards can significantly improve the performance and aesthetics of the boards.

● Chemical resistance: PET has excellent chemical corrosion resistance and can resist the erosion of various chemicals such as acids, alkalis, greases, etc. This makes PET MDF boards have significant advantages in environments that are susceptible to chemical contamination, such as kitchens and bathrooms.

● Heat resistance: PET film has good heat resistance and can remain stable at high temperatures, and is not easy to deform or damage. Therefore, PET MDF boards can also maintain good use effects in high temperature environments.

● Mechanical strength: PET materials have high mechanical strength and good impact resistance. The surface hardness and wear resistance of MDF boards covered with PET film are significantly improved, which can effectively resist scratches and wear in daily use.

● Environmental performance: PET is an environmentally friendly material that can be recycled and reused, and has little pollution to the environment. PET MDF boards meet environmental protection standards during production and use, meeting the needs of modern society for environmentally friendly materials.

How to make PET MDF boards?

The manufacturing process of PET MDF board mainly includes the steps of substrate preparation (pretreatment processes such as grinding and cleaning), PET film lamination, hot pressing curing (under certain temperature and pressure) and surface treatment (such as grinding and polishing).

1. Substrate preparation:

First, select high-quality MDF board as the substrate. MDF board needs to go through pretreatment processes such as grinding and cleaning to ensure a smooth and clean surface to prepare for lamination.

2. PET film lamination:

The PET film is covered on the surface of the MDF board through hot pressing lamination technology. During the hot pressing lamination process, the PET film is firmly combined with the MDF board under high temperature and high pressure to form a uniform and dense protective film.

3. Hot pressing curing:

The laminated MDF board enters the hot pressing curing equipment and is cured under certain temperature and pressure. The curing process ensures that the bond between the PET film and the MDF board is more solid and improves the overall performance of the board.

4. Surface treatment:

The cured PET MDF board undergoes surface treatment processes such as grinding and polishing to further improve the surface quality and decorative effect of the board.

What are the advantages of PET MDF board?

Advantages of PET MDF board: excellent surface performance (smooth and flat surface), environmental protection performance (recyclable and reusable), waterproof and moisture-proof (effectively prevent moisture and moisture), easy to clean (not easy to accumulate dust) and diversified decorative effects.

1. Excellent surface performance:

The surface of the MDF board covered with PET film is smooth and flat, with high gloss and good decorative effect. At the same time, the wear resistance, scratch resistance and chemical resistance of the PET film significantly improve the service life of the board.

2. Environmental performance:

PET is a recyclable and reusable environmentally friendly material. PET MDF board meets environmental protection standards during production and use, does not contain harmful substances, and is harmless to the environment and human health.

3. Waterproof and moisture-proof:

PET film has good waterproof and moisture-proof properties, which can effectively prevent the intrusion of moisture and moisture, and prevent the MDF board from deforming and expanding in a humid environment.

4. Easy to clean:

PET MDF board has a smooth surface, is not easy to accumulate dust, and is easy to clean. Just wipe it gently with a damp cloth to keep the surface clean. It is especially suitable for places that need frequent cleaning, such as kitchens and bathrooms.

5. Diverse decorative effects:

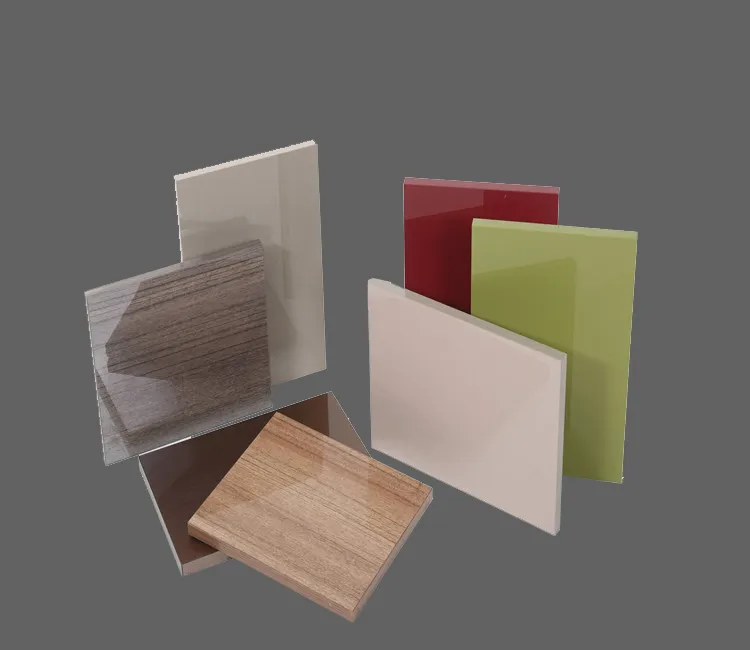

PET MDF board can achieve colorful decorative effects through PET films of different colors, patterns and textures to meet different styles and personalized needs.

What are the application areas of PET MDF board?

The application areas of PET MDF board are: furniture manufacturing (cabinets, wardrobes, bookshelves, etc.), interior decoration (wall decorative panels, ceiling materials, etc.), commercial display (display cabinets, booths, etc.), kitchens and bathrooms (cabinet door panels, bathroom cabinets, etc.), office furniture (desks, filing cabinets, etc.).

1. Furniture manufacturing: PET MDF board has been widely used in furniture manufacturing due to its excellent surface properties and environmental protection characteristics. For example, furniture products such as cabinets, wardrobes, bookshelves, tables and chairs can all use PET MDF boards, which are both beautiful and durable and environmentally friendly.

2. Interior decoration: In the field of interior decoration, PET MDF boards can be used for wall decoration panels, ceiling materials, door panels, etc. Its smooth surface and rich decorative effects can add fashion and modernity to the interior space.

3. Commercial display: PET MDF boards are also widely used in commercial display and exhibition fields, such as display cabinets, booths, billboards, etc. Its high gloss and durability make the display effect more outstanding and attract customers' attention.

4. Kitchen and bathroom: Because PET MDF boards have good waterproof and moisture-proof properties, they are also widely used in humid environments such as kitchens and bathrooms. For example, cabinet door panels, bathroom cabinets, laundry room decorative materials, etc., can all use PET MDF boards, which are both beautiful and durable, and easy to clean.

5. Office furniture: PET MDF boards are also widely used in the field of office furniture, such as desks, filing cabinets, partition boards, etc. Its smooth surface and easy-to-clean characteristics make the office environment more tidy and orderly.

Conclusion

In summary, PET MDF board is a new composite material with PET film on the surface of medium-density fiberboard. PET film has excellent chemical resistance, heat resistance, mechanical strength and environmental protection performance, which makes PET MDF board have broad application prospects in furniture manufacturing, interior decoration and commercial display.