What is the use of UV MDF board? What is special about it?

2024-07-05 15:30

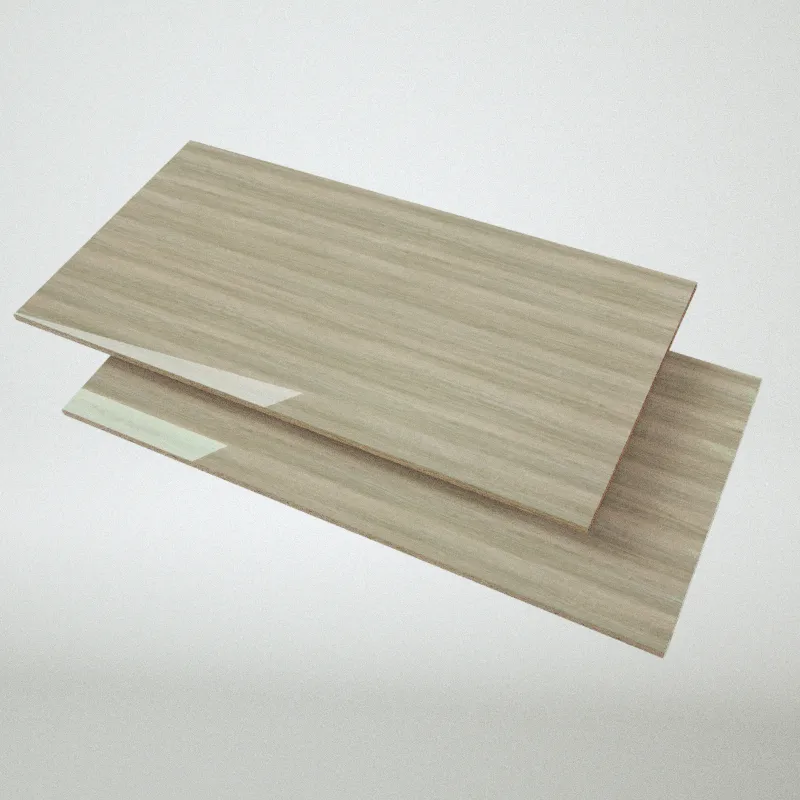

UV MDF board is gradually favored by consumers and designers because of its high gloss, strong wear resistance and environmental protection. So, what are the uses of UV MDF board? What is special about it?

This article will discuss in detail the basic concepts, characteristics, main uses and special features of UV MDF board.

What is UV MDF board?

UV MDF board is a board that is UV-cured on the surface of medium-density fiberboard (MDF board). MDF board is made of wood fiber and synthetic resin pressed under high temperature and high pressure, while UV treatment is to apply a layer of UV coating on the surface of MDF board and quickly cure it through ultraviolet light.

Production process of UV MDF board

The production process of UV MDF board includes the steps of substrate production, surface treatment, coating of UV coating and UV curing.

● Substrate production: First, produce MDF board that meets quality standards to ensure its smooth surface and uniform density.

● Surface treatment: The surface of MDF board is pre-treated by sanding, cleaning, etc. to ensure that the coating can be evenly adhered.

● UV coating: Apply a layer of UV coating evenly on the surface of the MDF board.

● UV curing: Through UV irradiation, the coating is quickly cured to form a protective layer with high hardness and good gloss.

What are the characteristics of UV MDF board?

Characteristics of UV MDF board: high gloss, strong wear resistance, good environmental protection (no organic solvents), easy to clean (not easy to stain), and UV resistance.

1. High gloss:

The UV coating has high gloss and can present a mirror effect, making the surface of the board more beautiful. This high gloss not only enhances the visual effect of the board, but also gives it higher decorativeness.

2. Strong wear resistance:

The UV coating has high hardness and good wear resistance, which can effectively resist scratches and wear in daily use. This allows the UV MDF board to maintain a smooth surface state after long-term use.

3. Good environmental protection:

The UV coating does not contain organic solvents, and no harmful substances are released during the curing process, which meets environmental protection requirements. The environmental performance of UV MDF board makes it popular in modern home decoration, especially for families and public places with high environmental protection requirements.

4. Easy to clean:

The surface of UV MDF board is smooth, not easy to stain, and easy to clean and maintain daily. Just wipe it gently with a damp cloth to easily remove dust and stains on the surface, keeping the board clean and beautiful.

5. Anti-ultraviolet:

The UV coating has good anti-ultraviolet performance and can effectively prevent fading and aging caused by sunlight. This allows UV MDF board to maintain bright colors and strong texture for a long time in an environment with direct sunlight.

What is the use of UV MDF board?

The use of UV MDF board: furniture manufacturing (cabinets, wardrobes, bookshelves, tables and chairs), interior decoration (walls, ceilings, door panels), commercial display (display cabinets, exhibition stands).

1. Furniture manufacturing:

UV MDF board is widely used in furniture manufacturing, mainly used to make cabinets, wardrobes, bookshelves, tables and chairs and other furniture. Its high gloss and wear resistance make the furniture not only beautiful and generous, but also have a long service life.

● Cabinets: The high gloss and stain resistance of UV MDF board make it an ideal material for making kitchen cabinets. It can resist the erosion of oil smoke and stains, keeping the cabinets clean and tidy.

● Wardrobe: The UV MDF board used for wardrobe production not only has a bright appearance, but also can resist daily friction and collision, protecting the storage environment of clothing.

● Bookshelves and tables and chairs: Bookshelves and tables and chairs made of UV MDF board have smooth surfaces and solid structures, making them popular in study and office environments.

2. Interior decoration:

UV MDF board is widely used in wall, ceiling, door panel and other decorations in interior decoration to meet the decoration needs of different styles.

● Wall decoration: UV MDF board is used for wall decoration, which can create a high-end and fashionable indoor atmosphere, suitable for modern simplicity, European classical and other decoration styles.

● Ceiling decoration: The lightweight characteristics of UV MDF board make it an ideal material for ceiling decoration, which is beautiful and does not increase the burden on the building structure.

● Door panel decoration: UV MDF board used for door panel decoration not only improves the appearance and texture of the door, but also has the practical characteristics of wear resistance and easy cleaning.

3. Commercial display:

UV MDF board also has important applications in commercial display, including display cabinets and exhibition racks in shopping malls, exhibitions and other places, which are both beautiful and practical.

● Display cabinet: Display cabinets made of UV MDF board, with smooth surface and bright colors, can attract customers' attention and enhance the display effect of goods.

●Exhibition rack: Using UV MDF board to make exhibition racks in exhibitions can not only withstand frequent disassembly and transportation, but also maintain a good appearance and enhance the display effect of exhibits.

What is special about UV MDF board?

The special features of UV MDF board: good durability, environmental protection performance, high gloss effect, easy maintenance, and diversified design.

1. Good durability:

The durability of UV MDF board is one of its major features. The surface hardness after UV curing is greatly improved, which can resist wear and scratches in daily use and extend the service life of the board.

2. Environmental performance:

The environmental performance of UV MDF board is particularly outstanding. Its production process does not use organic solvents, and no harmful substances are released during the curing process, which meets modern environmental protection standards. UV MDF board is undoubtedly an ideal choice for families and public places that pay attention to health and environmental protection.

3. High gloss effect:

The high gloss effect of UV MDF board gives it a unique advantage in decoration. The mirror-like smooth surface not only enhances the visual effect, but also reflects light, increasing the brightness and sense of space in the room.

4. Easy maintenance:

The surface of UV MDF board is smooth, not easy to stain, and easy to clean and maintain daily. Just wipe it gently with a damp cloth to keep the board clean as new. This greatly reduces the time and cost of cleaning and maintenance for busy modern families and commercial places.

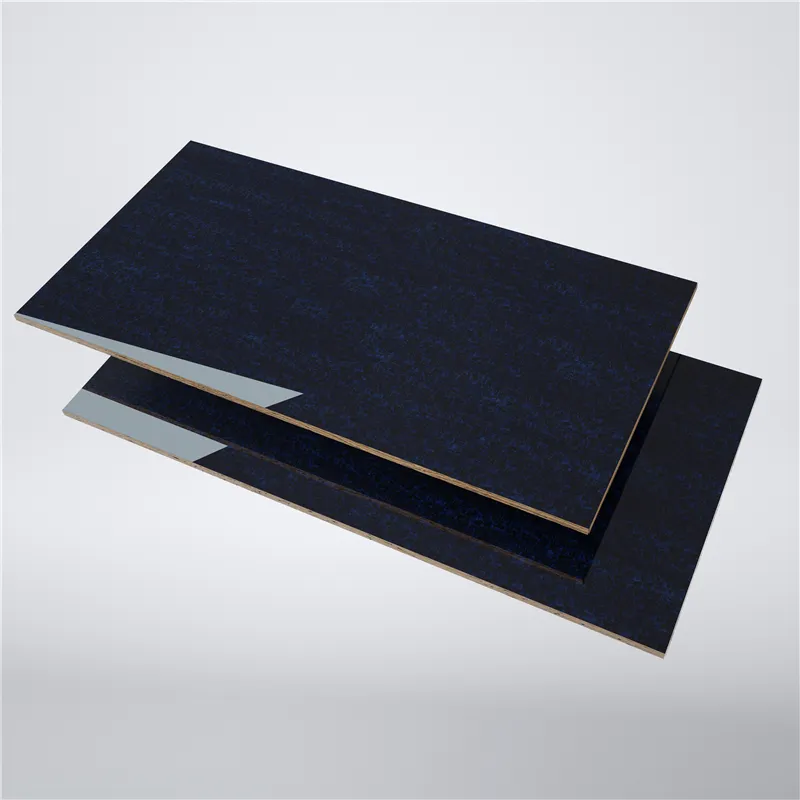

5. Diversified design:

UV MDF board can achieve various colors and patterns through different coatings and processes to meet diverse decoration needs. From modern simplicity to European classical, UV MDF board can create different styles of decorative effects through its unique design and color.

Conclusion

As an environmentally friendly, high-performance and beautiful new material, UV MDF board has broad application prospects in furniture manufacturing and interior decoration. Through reasonable selection and use, UV MDF boards can bring higher decorative effects and usage experience to the home environment.