Which is more expensive, MDF board or HDF board?

2024-07-16 15:30

Medium-density fiberboard (MDF) and high-density fiberboard (HDF) are two commonly used man-made boards in modern furniture manufacturing and interior decoration. Due to their differences in processing performance, application areas and costs, consumers and manufacturers often face confusion when choosing.

This article will deeply analyze the price composition, market application and respective advantages and disadvantages of MDF and HDF boards to help readers better understand the economy and applicability of these two materials.

Basic Overview of MDF and HDF Boards

What is MDF Board?

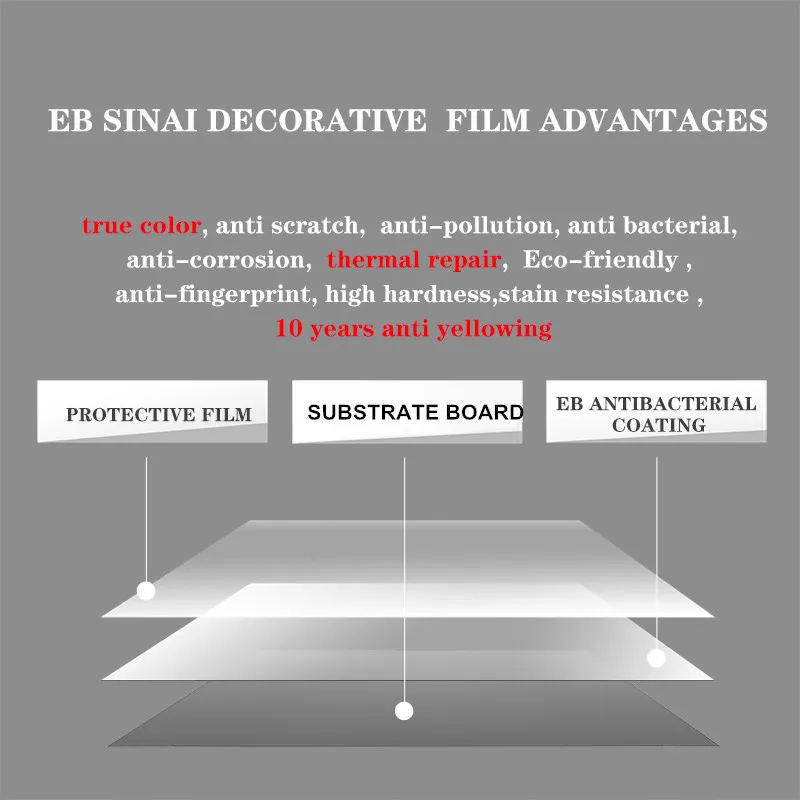

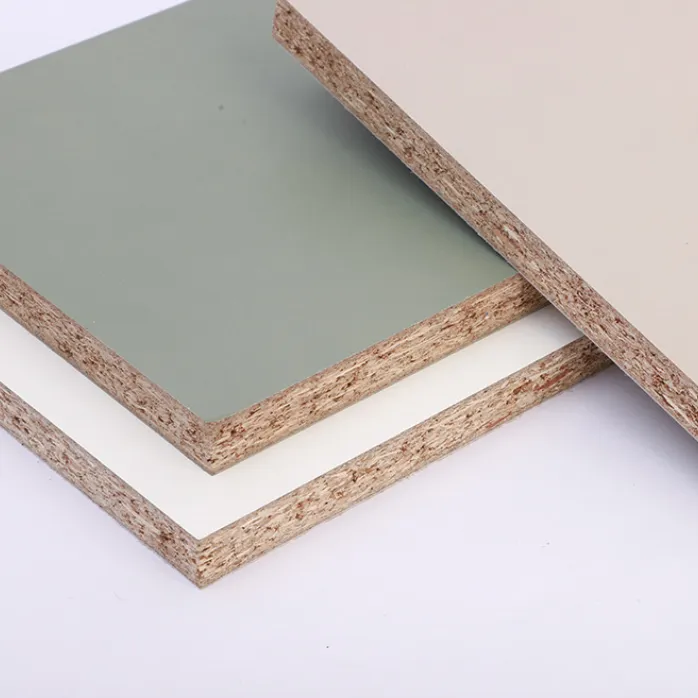

MDF board, or medium-density fiberboard, is a man-made board made by combining wood fiber with synthetic resin and pressing it under high temperature and high pressure. MDF board has the advantages of flat and smooth surface, uniform density and easy processing, and is widely used in furniture, cabinets, door panels, wall panels and other fields.

What is HDF board?

HDF board, or high-density fiberboard, has a similar production process to MDF board, but its density is higher. The density of HDF boards is usually more than 800 kg/m3, which is harder, more wear-resistant and more impact-resistant than MDF boards. Therefore, HDF boards are more common in application scenarios with high strength and high wear resistance requirements, such as floor substrates, decorative panels, etc.

Analysis of price components of MDF boards and HDF boards

1. Raw material cost

The main raw materials of MDF boards and HDF boards are wood fibers and synthetic resins, but the raw material selection of HDF boards is more stringent, requiring higher fiber purity and better quality resins. This leads to the raw material cost of HDF boards being usually higher than that of MDF boards.

2. Production process

The production of HDF boards requires higher pressing pressures and higher temperatures to achieve their high density and high strength requirements. This makes the production process of HDF boards more complicated, with higher equipment requirements and greater energy consumption, resulting in higher production costs.

3. Product performance

Due to the higher density of HDF boards, their mechanical properties and wear resistance are better than those of MDF boards, so they have a longer life in high-intensity use environments. This performance advantage is also reflected in the price, and HDF boards are usually more expensive than MDF boards.

4. Market demand

Market demand is also an important factor affecting prices. Due to the better performance of HDF boards, there is a large demand for them in high-end markets such as flooring and decorative panels, which also leads to their generally higher prices than MDF boards.

Market price comparison of MDF boards and HDF boards

According to market research data, there are significant differences in the prices of MDF boards and HDF boards. Taking standard thickness boards as an example, the market price of MDF boards is approximately between US$15-25 per square meter, while the price of HDF boards is between US$25-40 per square meter. The specific price will also be affected by factors such as brand, origin, and specifications.

1. Regional differences

Different wood resources, production costs and market demands in different regions lead to differences in the prices of MDF boards and HDF boards in different regions. For example, in North America, due to the abundance of wood resources, the prices of MDF boards and HDF boards are relatively low; while in some European and Asian countries, wood resources are relatively scarce and the prices of boards are higher.

2. Brand influence

Well-known brands of MDF boards and HDF boards are usually more expensive than ordinary brands because of their advantages in quality, environmental protection and after-sales service. For example, the price of HDF board of a well-known international brand may be as high as more than US$50 per square meter, while the price of HDF board of an ordinary brand is around US$30.

3. Product specifications

The thickness, size, surface treatment and other specifications of MDF and HDF boards will also affect the price. Thicker, larger and specially surface-treated boards are usually more expensive. For example, the price of HDF board with a thickness of 25 mm is significantly higher than that of HDF board with a thickness of 12 mm.

Application scenarios and economic analysis of MDF and HDF boards

1. Furniture manufacturing

In furniture manufacturing, MDF boards are widely used in cabinets, bookshelves, bedside tables and other products due to their flat and smooth surface, easy processing and relatively low price. HDF boards are often used in furniture parts that need to withstand greater pressure and frequent use, such as tabletops, chair seats, etc., due to their high strength and high wear resistance.

2. Flooring materials

In floor manufacturing, HDF boards have become the main substrate for laminate flooring due to their excellent wear resistance and stability. Despite its high price, its superior performance and long service life make it an important player in the high-end flooring market. MDF boards are usually not used for floor substrates due to their low density and poor wear resistance, but they are also used in some low-end floors and temporary laying.

3. Architectural decoration

In architectural decoration, both MDF and HDF boards are widely used. MDF boards are often used for decorative parts such as wall panels, ceilings and decorative lines because they are easy to carve and paint. HDF boards are often used in wall decorative panels, door panels and other scenes that require higher strength and durability because of their good impact resistance and moisture resistance.

Consumer selection suggestions

1. Budget considerations

For consumers with limited budgets, MDF boards are a cost-effective choice. They are relatively cheap and their performance is sufficient to meet most home and decoration needs. However, when choosing MDF boards, you should pay attention to choosing environmentally certified products to ensure that the formaldehyde emission meets safety standards.

2. Use environment

In high humidity and high wear environments, such as kitchens, bathrooms, floors, etc., it is recommended to choose HDF boards. Despite the higher price, its excellent moisture and abrasion resistance give it a longer service life and better performance in these environments.

3. Long-term investment

For consumers who focus on long-term investment, although HDF board has a higher initial cost, it may be more cost-effective in long-term use due to its higher durability and performance. Especially in the high-end furniture and flooring market, the advantages of HDF board are more obvious.

Conclusion

MDF board and HDF board have their own advantages and disadvantages in price, performance and application areas. In general, HDF board is usually more expensive than MDF board due to its higher raw material and production costs. However, when making specific choices, consumers should make comprehensive considerations based on their own budget, use environment and requirements for product performance.

Whether choosing MDF board or HDF board, it is crucial to ensure the environmental performance and health and safety of the product.