Will high-gloss EB sheet oxidize and darken?

2024-08-09 15:30

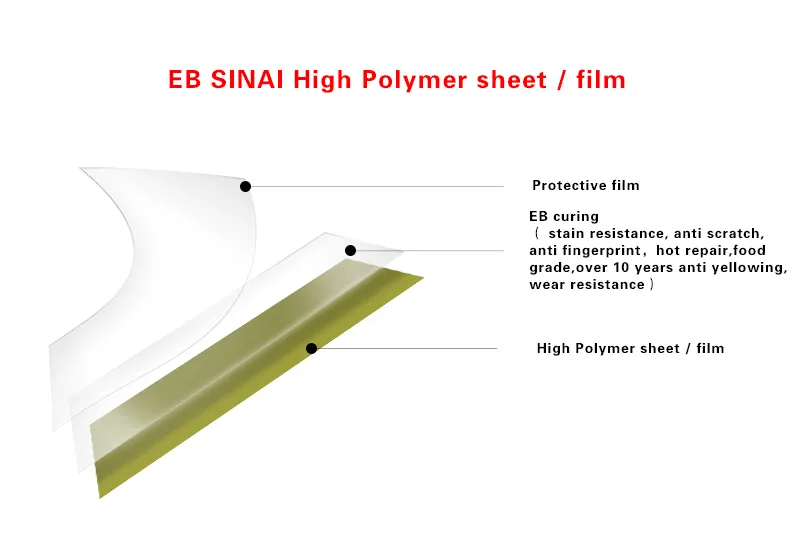

In the modern decorative materials market, high-gloss EB (Electron Beam) sheet is highly favored for its excellent gloss, wear resistance and environmental protection. However, many consumers are concerned about one question when choosing this material: Will high-gloss EB sheet oxidize and darken? This article will explore the characteristics of high-gloss EB sheet, the causes of oxidation and its impact on the material, to help readers fully understand this issue.

Basic characteristics of high-gloss EB sheet

High-gloss EB sheet is a decorative material processed by electron beam curing process, with the following excellent characteristics:

1. High gloss: After electron beam curing, the surface of high-gloss EB sheet has extremely high gloss and presents a mirror effect, which can greatly enhance the decorative effect and visual beauty.

2. Wear resistance: Because the electron beam curing technology gives the sheet surface a high hardness, high-gloss EB sheet has excellent wear resistance and can resist scratches and wear in daily use.

3. Chemical resistance: High-gloss EB sheet has good tolerance to a variety of chemicals, is not easily corroded by acids, alkalis, solvents and other substances, and is suitable for a variety of environmental conditions.

4. Environmental protection: Electron beam curing technology does not use solvents, reduces the emission of harmful substances, and meets the needs of modern society for environmentally friendly materials.

Causes and effects of oxidation of high-gloss EB sheets

Oxidation refers to the process in which the material reacts chemically with oxygen, resulting in changes in the properties of the material. In high-gloss EB sheets, oxidation is mainly manifested as surface darkening and decreased gloss. The main causes of oxidation are as follows:

1. Ultraviolet radiation: Ultraviolet rays are one of the main causes of EB sheet oxidation. Long-term exposure to sunlight will destroy the molecular structure of the surface of EB sheets, causing color fading and decreased gloss.

2. Oxygen contact: Oxygen in the air reacts chemically with the surface of the material, which is an important cause of oxidation. Although high-gloss EB sheets have a certain degree of oxidation resistance, oxidation may still occur if they are exposed to the air for a long time.

3. Environmental pollution: Pollutants in the air such as sulfur dioxide and nitrogen oxides will also accelerate the oxidation process of the material, resulting in darkening of the surface and decreased gloss.

4. Temperature changes: Frequent temperature changes will accelerate the aging and oxidation process of the material, especially in high temperature environments, the oxidation reaction will be more intense.

How is the antioxidant performance of high-gloss EB sheet?

In order to improve the antioxidant performance of high-gloss EB sheet, manufacturers have taken a series of technical measures during the production process:

1. Electron beam curing technology: Electron beam curing technology gives the surface of high-gloss EB sheet a highly cross-linked molecular structure, enhances its chemical resistance and UV resistance, and reduces the possibility of oxidation.

2. Antioxidant addition: During the production process, manufacturers usually add antioxidants. These additives can capture free radicals and inhibit the oxidation reaction, thereby slowing down the oxidation rate of the material.

3. Surface protective coating: Some high-gloss EB sheets will be coated with a protective coating on the surface. This coating not only enhances the wear resistance of the sheet, but also effectively isolates oxygen and ultraviolet rays, further improving its antioxidant performance.

Performance of high-gloss EB sheet in practical applications

The high-gloss EB sheet treated with the above technology shows good antioxidant performance in practical applications. However, despite this, users still need to pay attention to some matters during use to ensure that it maintains high gloss for a long time.

1. Avoid long-term direct sunlight: Although high-gloss EB sheets have certain UV resistance, long-term exposure to direct sunlight may still cause oxidation and discoloration. Therefore, when used outdoors, try to avoid direct sunlight or take sunshade measures.

2. Regular cleaning and maintenance: Clean the surface of the sheet regularly to remove dust and dirt, and avoid the accumulation of pollutants to accelerate the oxidation process. Use a neutral detergent and a soft cloth for cleaning, and avoid using detergents containing strong acids or strong alkalis.

3. Avoid extreme environments: Under extreme environmental conditions, such as high temperature, humidity, and severe pollution, the anti-oxidation properties of high-gloss EB sheets may be affected. Therefore, long-term use in these environments should be avoided as much as possible.

4. Regular inspection and maintenance: Regularly check the surface condition of high-gloss EB sheets. If the surface gloss is found to be reduced or darkened, maintenance measures should be taken in time, such as re-grinding and polishing, to restore its gloss.

What are the advantages of using high-gloss EB sheets?

Despite the possibility of oxidation and darkening, high-gloss EB sheets still have significant advantages in a variety of applications due to their excellent performance and aesthetic effects.

1. Interior decoration: High gloss EB sheet is widely used in interior decoration, such as cabinets, furniture, wall panels and ceilings, due to its excellent gloss and aesthetic effect. Its wear resistance and chemical resistance make it perform well in daily use and easy to clean and maintain.

2. Commercial display: High gloss EB sheet is also widely used in commercial display, such as display cabinets, display racks and billboards. Its high gloss can attract customers' attention and enhance the display effect.

3. Industrial application: The chemical resistance and wear resistance of high gloss EB sheet make it also have broad prospects in industrial applications, such as equipment housing, mechanical shield and work surface.

4. Medical field: Due to the environmental protection and chemical resistance of high gloss EB sheet, its application in the medical field is also gradually increasing, such as medical equipment housing, laboratory countertops and ward decoration.

Conclusion

High gloss EB sheet is widely used in various decoration and industrial fields due to its excellent gloss, wear resistance and environmental protection characteristics. Although it performs well in anti-oxidation properties, in actual use, it is still necessary to avoid long-term direct sunlight, regular cleaning and maintenance, and avoid extreme environments to ensure that it maintains high gloss for a long time.