PET board

2023-09-13 15:30

PET board

What is PET board?what materials do PET boards consist of, and its advantages & application

01. What is PET?

PET refers to PET plastic (polyvinylterephthalate resin plastic), commonly found in mineral water bottles, carbonated beverage bottles, cling films, or edible oil packaging bottles, plastic boxes, etc. The molding process of PET plastic can include injection molding, extrusion, blow molding, coating, bonding, machining, electroplating, vacuum metal plating, and printing.

02. What is PET board?

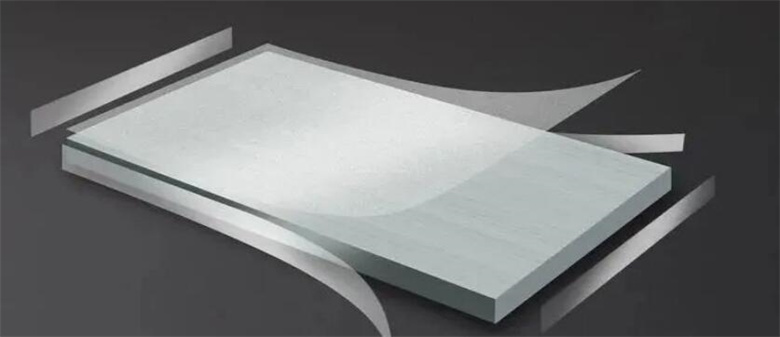

PET board mainly refers to the surface of the board laminated with PET film, which is usually 0.35-0.5mm thick. There are many types of substrates for PET boards, including OSB board, MDF board, particle board, and plywood board. Among them, MDF board is the optimal choice for PET board substrate, because the particles of density board are small, and the flatness of PET decorative panel made of density board is the best among the above types of boards.

PET film laminated onto the substrate by PUR laminating machine equipment is called PET board.

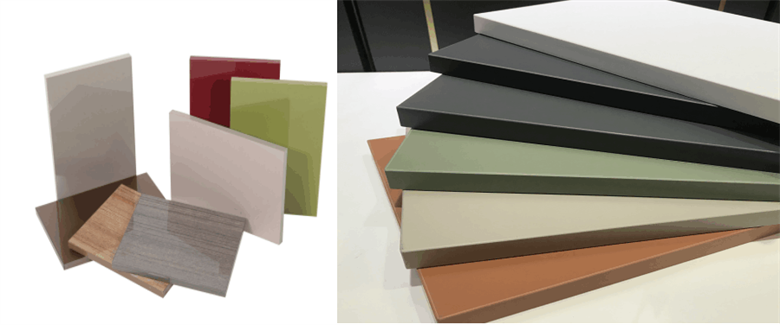

03. Classification of PET boards

PET board can be divided into glossy and matte surfaces.

The bright surface of PET board is like a mirror high gloss, with a brightness of up to 100 degrees; Pet matte surface, commonly referred to as skin sensation, as the name suggests, It feels like touching a baby's skin with your hands, with a smooth and delicate texture.

04. Characteristics of PET board

Advantages :

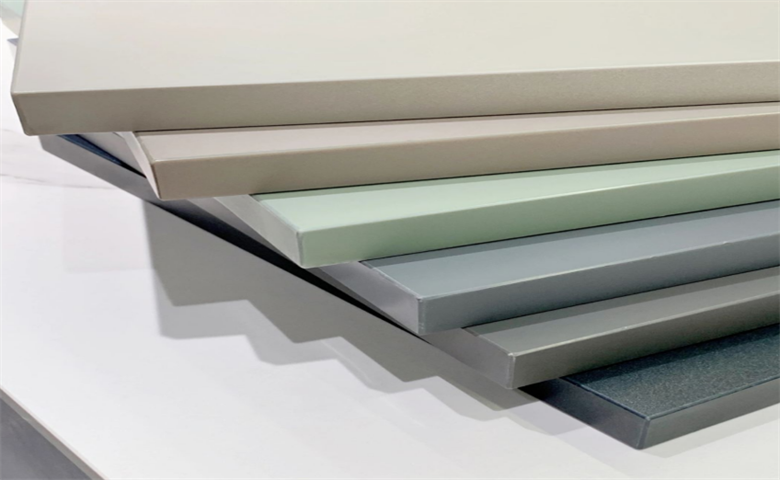

① Rich and beautiful

The choice of colors is diverse, with the most common being pure white, off white, light gray, light coffee, etc., which can be well integrated with several popular styles such as cream style, high-end gray style, medieval style, minimalist style, etc. It can also be perfectly matched and integrated with popular elements such as wood grilles, rock slabs, micro cement, and other emerging materials. Has extremely high appearance and aesthetic effects.

② Safety and environmental protection

The material has no added chemical or metal substances in terms of composition, and meets absolute food grade standards in terms of safety. It is colorless, odorless, non-toxic, and does not cause any harm to the human body. Nowadays, many plastic bottles and food packaging boxes use PET materials.

③ Stable performance

The PET film itself is a type of resin material, and due to its unique characteristics and properties, it has created superior properties such as wear resistance, scratch resistance, acid and alkali corrosion resistance, compression resistance, and high temperature resistance of the PET film.

④ Wear and stain resistant

PET flat film has obvious advantages of wear resistance, scratch resistance, pressure resistance, high temperature resistance, corrosion resistance, and aging resistance due to its material structure characteristics and stable performance. Not afraid of collapsing or bumping. Excellent anti fouling performance and easy to clean

05. Process of PET board

PET board is made by pressing PET film onto the base board by PUR laminating machine equipment. PET film is a layer of film on the surface and is also made by high-pressure extrusion of PET raw materials. Due to this processing method, the PET film itself does not have any texture and is pure color.

06. Application Fields of PET Board

PET board is still a very environmentally friendly type among many boards, widely used in various fields, often used on cabinet doors and door panels, and some even used for counter tops and desks. Minimalist, clean, and atmospheric.

PS: Zhihua Group has been specializing in home decoration materials for 25 years, mainly producing products such as EB SINAI decorative film/film, PETG film/sheet, acrylic sheet, UV board, PET board, EB board, acrylic MDF board , and matching color edge banding .

Welcome inquiry: 0086-18676549165, email: dayipetg@163.com.