Stain Resistance Hot Repair Super Matte Marble Decorative Film

item code : TAD-3001

Marble PETG advantages: color stable,anti scratch,wear resistance,anti fingerprint,high hardness,Eco-friendly,anti yellowing,stain resistance

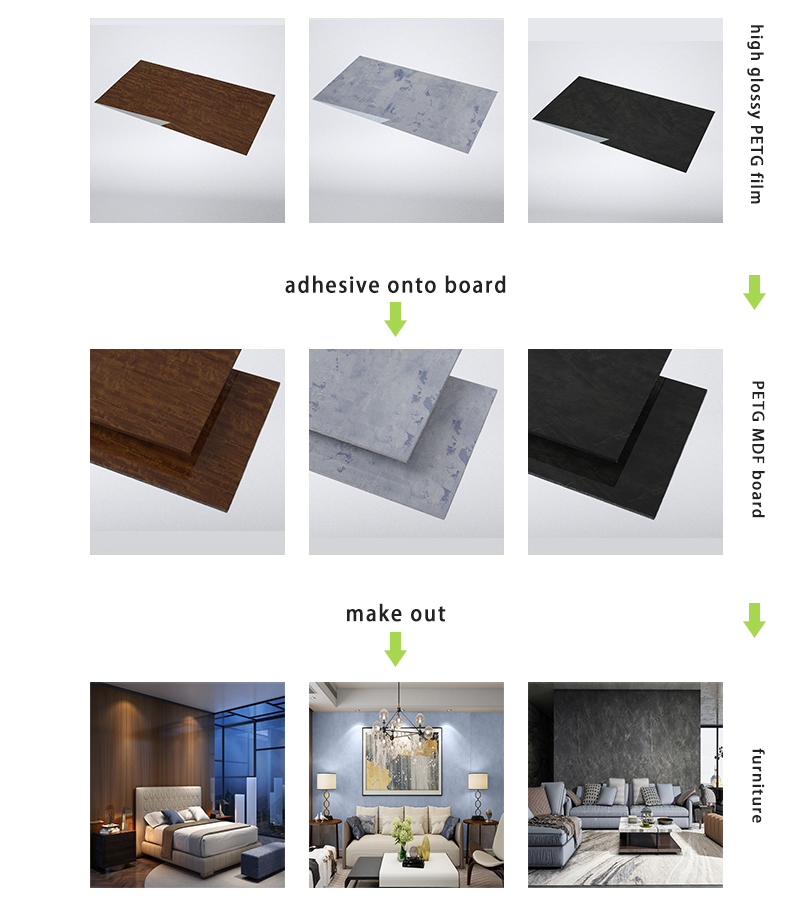

How PETG film Production technology: Using PUR laminate machine line laminate petg film/sheet onto various substrates,such as : MDF board, plywood board, particle wood board, aluminum honeycomb board, PVC foam board and other flat plates.

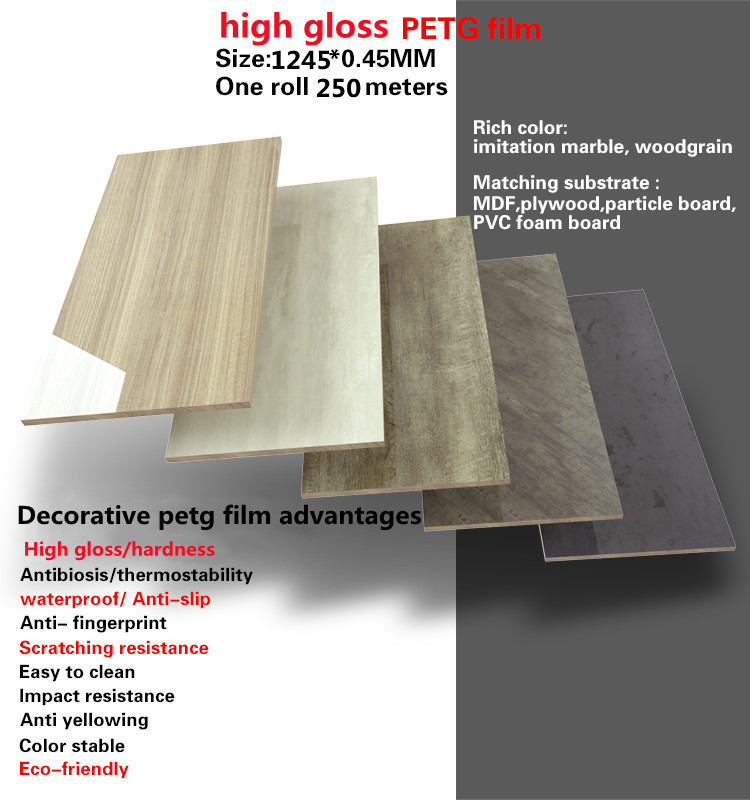

Woodgran Design Color Anti Yellowing Anti Scratch Stain Resistance Super Matte Stain Resistance Food Grade Easy to clean Wear Resistance Eco- friendly PETG Film.

Material : PETG film |

Size: 1245MM width * 0.45MM thickness |

Characteristics: |

1. Anti scratch resistance |

2. High impact strength - no damage during process |

3. Food grade ,no bad smelling |

4.High gloss mirror effect, very flat |

5.Easy to cut, no edge crack |

6.Durable for long life |

7.Good resistance to UV light , color stability |

8.Good weather resistance (even under 40 Celsius degree , it works) |

9.Good chemical resistance |

10. Waterproof |

Applied field: cabinet door panel, wardrobe door panel, bathroom cabinet, wall panel, ecological door, office furniture, commercial space,ETC. |

Pattern Design PETG Film rich color , with many advantages:

color stability, high hardness, super wear-resistant, anti-scratch, anti yellowing , anti-fingerprint, Eco-friendly, heat resistance, resistance Pollution and burning resistance.

Pattern deesign PETG film surface coating technology : can be treated by excimer technology coating or EB coating technology .

How process the PETG sheet onto substrate board : Using PUR laminte machine line laminte the sheet onto substrate board.

Pattern design PETG sheet application: cabinet door panel, wardrobe door panel, bathroom cabinet, wall panel, ecological door, office furniture, commercial space,ETC.