Are PETG film and PETG sheet the same? What's the difference between them?

2024-08-08 15:30

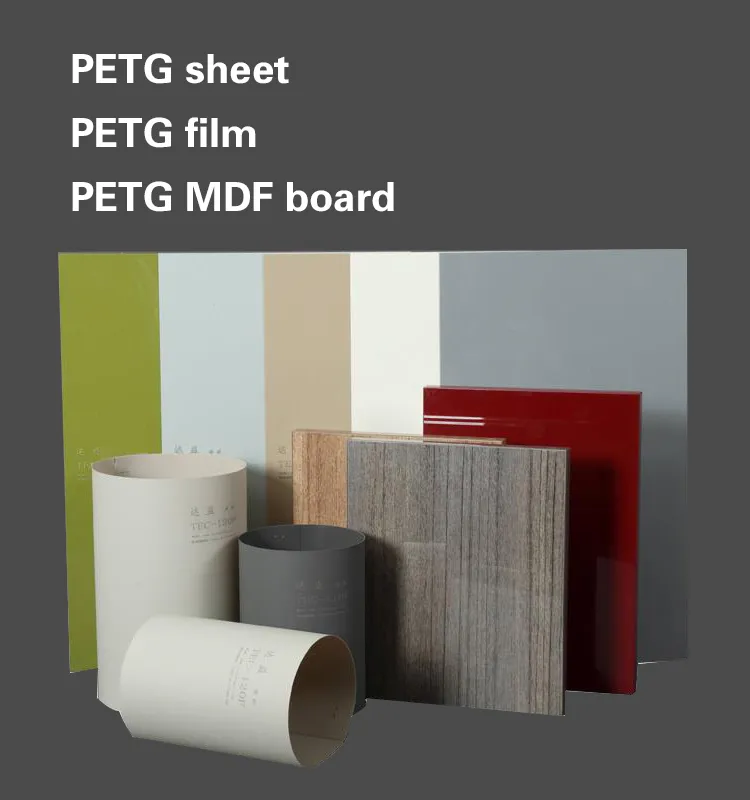

In modern industry and daily life, PETG (polyethylene terephthalate copolymer) materials are widely used due to their excellent physical and chemical properties. Although PETG film (Film) and PETG sheet (Sheet) are both made of the same material, they have significant differences in manufacturing processes, performance characteristics and application fields.

This article will delve into the differences between PETG film and PETG sheet to help readers fully understand these two materials.

What is PETG material?

PETG is a transparent thermoplastic polyester material with high transparency, excellent chemical resistance, excellent impact resistance and good processability. These properties make PETG widely used in packaging, electronics, medical and advertising display and other fields.

Characteristics of PETG materials:

1. High transparency: PETG material has excellent transparency and gloss, and can provide good visual effects.

2. Chemical resistance: PETG has good resistance to a variety of chemicals and is suitable for applications in contact with various chemical substances.

3. Impact resistance: PETG material has excellent impact resistance and can withstand large external impacts without easily breaking.

4. Processability: PETG material has good thermoformability and processability, and is suitable for a variety of processing techniques.

Are PETG film (Film) and PETG sheet (Sheet) the same?

What is PETG film?

PETG film refers to a thin PETG material, usually less than 0.1 mm thick. PETG films are known for their flexibility and ease of processing and are widely used in packaging, labels, cover films and other fields.

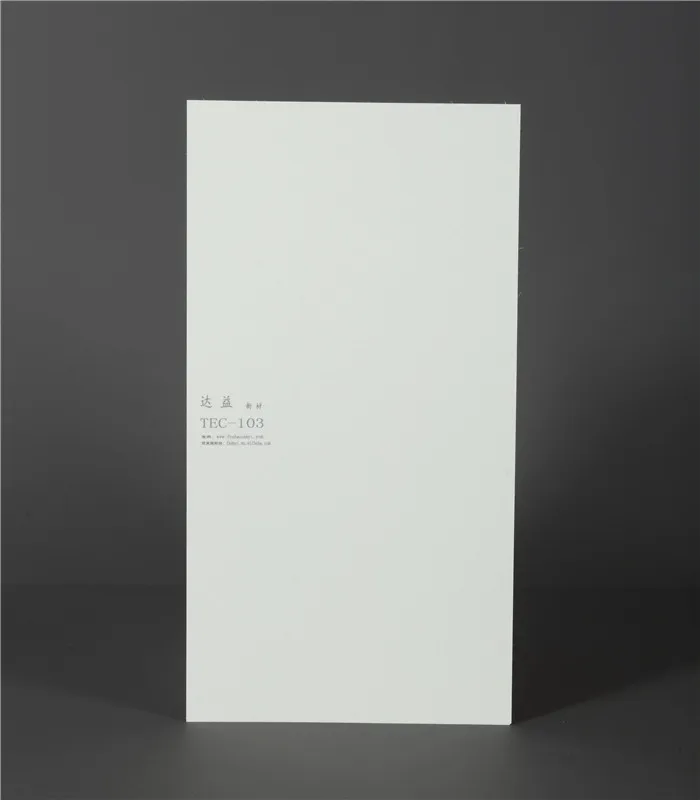

What is PETG sheet?

PETG sheet refers to a thicker PETG material, usually more than 0.5 mm thick. PETG sheets have high rigidity and strength and are widely used in advertising display boards, mechanical shields, electronic equipment casings and other fields.

What is the difference between PETG film (Film) and PETG sheet (Sheet)?

★ Difference 1. Difference in manufacturing process:

Manufacturing process of PETG film PETG film is usually manufactured by extrusion blow molding or calendering. Specific steps are as follows:

1. Raw material preparation: PETG pellets are fed into the extruder.

2. Extrusion molding: PETG particles are melted at high temperature and extruded through a die to form a film.

3. Cooling and shaping: The extruded film is cooled and shaped by cooling rollers.

4. Rewinding: The shaped film is rolled into rolls for subsequent processing and use.

Manufacturing process of PETG sheets PETG sheets are usually manufactured by extrusion and calendering. Specific steps are as follows:

1. Raw material preparation: PETG pellets are fed into the extruder.

2. Extrusion molding: PETG particles are melted at high temperature and extruded through a die to form a sheet.

3. Cooling and shaping: The extruded sheet is cooled and shaped by cooling rollers.

4. Cutting: The shaped plates are cut and processed according to needs.

★ Difference 2, difference in performance characteristics:

●Thickness and rigidity:

1. PETG film: Thin thickness, usually less than 0.1 mm, with high flexibility and bendability.

2. PETG sheet: thicker, usually above 0.5 mm, has high rigidity and strength, and can withstand large external forces.

● Transparency and optical properties:

1. PETG film: Due to its thinner thickness, it has higher transparency and optical properties, and is suitable for applications requiring high transparency.

2. PETG sheet: Although it also has good transparency, due to its thicker thickness, its transparency is slightly less than that of PETG film, and it is more used for structural applications.

● Impact resistance:

1. PETG film: Due to its flexibility and bendability, it has good impact resistance, but its strength is not as good as that of the sheet.

2. PETG sheet: Due to its higher rigidity and strength, its impact resistance is better than that of film, and it can withstand large external impacts.

● Processability:

1. PETG film: It is easy to process such as thermoforming, printing, and lamination, and is suitable for various complex processing techniques.

2. PETG sheet: It also has good processability, but due to its large thickness, the processing difficulty is slightly higher than that of film. It is suitable for cutting, drilling, bending and other processing techniques.

★ Difference 3, difference in application fields:

●Application fields of PETG film:

1. Packaging materials: PETG film is often used in the packaging of food, medicine, and daily necessities, providing good protection and display effects.

2. Labels and laminations: PETG film is often used for product labels and surface laminations, providing excellent printing effects and wear resistance.

3. Electronic products: PETG film can be used as a protective film for electronic products and on the surface of display screens to provide good protection and visual effects.

4. Medical materials: PETG films are widely used in medical devices and medical packaging to ensure safety and hygiene.

●Application areas of PETG sheets:

1. Advertising display: PETG sheets are often used in advertising display boards, signs, display stands, etc., providing good display effects and durability.

2. Mechanical shields: PETG sheets are often used as shields and protective covers for mechanical equipment, providing excellent impact resistance and protective properties.

3. Building decoration: PETG sheets can be used for interior and exterior decoration of buildings, such as wall decorative panels, ceiling materials, etc., providing aesthetics and functionality.

4. Electronic equipment: PETG sheets are widely used in electronic equipment casings and structural parts, providing good protection and structural support.

Market prospects and development trends of PETG film (Film) and PETG sheet (Sheet)

As people's demand for environmentally friendly, safe and high-performance materials continues to increase, the market prospects for PETG films and PETG sheets are very broad.

1. Driven by environmental protection needs: Due to its recyclability and environmental protection performance, PETG materials meet the needs of modern society for environmentally friendly materials, and market demand continues to increase.

2. Promoted by technological progress: With the continuous advancement of material science and manufacturing technology, the performance and application scope of PETG films and PETG sheets continue to expand. The application of new materials and new processes has continuously enhanced the market competitiveness of PETG materials.

3. Diversified applications: The wide application of PETG film and PETG sheets in packaging, advertising, electronics, medical and other fields has promoted the rapid development of the market. In the future, as new application scenarios continue to emerge, the market potential of PETG materials will be further released.

Conclusion for PETG film and PETG sheet

In summary, although PETG film and PETG sheet are both PETG materials, there are significant differences in manufacturing processes, performance characteristics, and application fields.

PETG film is widely used in packaging, labels, electronic products and other fields due to its high transparency, flexibility and processability. PETG sheets are widely used in advertising displays, mechanical shields, building decoration and other fields due to their high rigidity, strength and impact resistance.