What are the advantages and disadvantages of high-gloss EB sheets?

2024-08-23 15:30

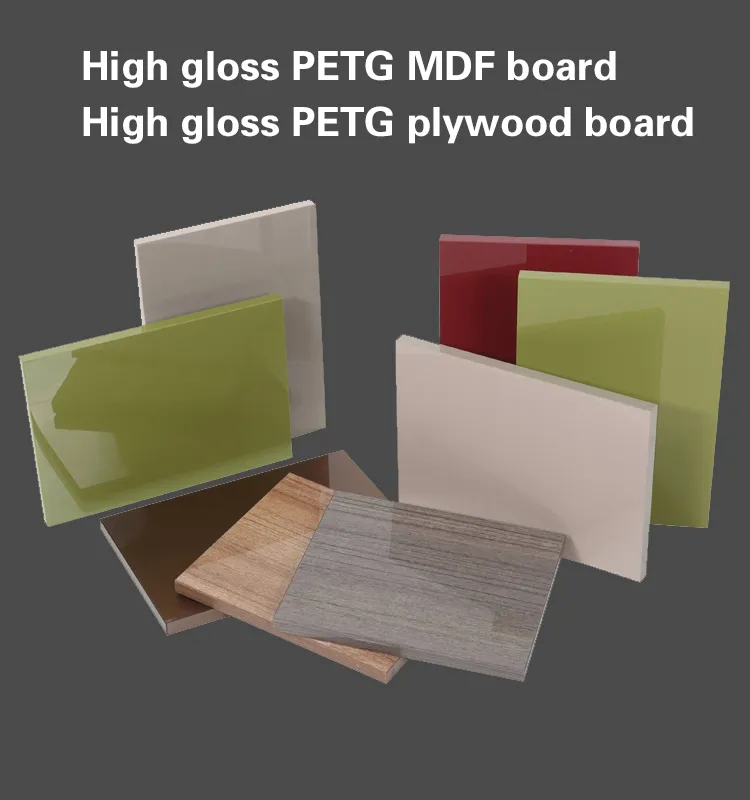

Among modern decorative materials, high-gloss EB (Electron Beam) sheets have gradually become a popular choice in the market due to their unique properties and excellent visual effects. Whether in interior decoration, furniture manufacturing, or advertising display, high-gloss EB sheets have shown strong application potential.

However, any material has its advantages and disadvantages, and understanding these characteristics is very important for reasonable use and purchase. This article will discuss the advantages and disadvantages of high-gloss EB sheets in detail to help readers fully understand this material.

What is high-gloss EB sheet?

High-gloss EB sheet is a high-gloss decorative sheet produced by electron beam curing technology. Electron beam curing is an advanced surface treatment process that quickly cures the coating through electron beam irradiation to form a high-gloss, high-hardness surface. This technology not only improves the gloss of the sheet, but also enhances its wear resistance and chemical corrosion resistance.

What are the advantages of high-gloss EB sheet?

Advantages of high-gloss EB sheet: high gloss (smooth surface, high brightness), excellent wear resistance (high-hardness coating), chemical corrosion resistance, easy to clean (not easy to accumulate dust and dirt), environmentally friendly and healthy, rich color selection.

1. High gloss:

The biggest feature of high-gloss EB sheet is its high gloss. Through the electron beam curing process, the surface of the sheet is smooth and bright, which can reflect a large amount of light and present a mirror-like effect. This high gloss not only enhances the decorative effect, but also enhances the brightness and visual impact of the space.

2. Excellent wear resistance:

The surface of the high-gloss EB sheet is treated with electron beam curing to form a high-hardness coating. This coating has excellent wear resistance and can effectively resist scratches and wear in daily use, extend the service life of the sheet and maintain its beauty.

3. Chemical corrosion resistance:

The electron beam cured coating also gives the high-gloss EB sheet good chemical corrosion resistance. Whether it is acid and alkali solution or various chemical cleaners, the coating can effectively resist corrosion, ensuring the stability and durability of the sheet in different environments.

4. Easy to clean:

The surface of high-gloss EB sheet is smooth, dust and dirt are not easy to accumulate, and it is very convenient to clean and maintain. Just wipe it gently with a damp cloth to keep the sheet as bright as new, reducing the frequency and cost of cleaning.

5. Environmental protection and health:

Electron beam curing technology is an environmentally friendly surface treatment process that does not use solvents and does not produce harmful gases during the curing process. High-gloss EB sheet does not contain harmful substances such as formaldehyde, meets environmental protection and health standards, and is suitable for places with high environmental protection requirements such as homes, hospitals and schools.

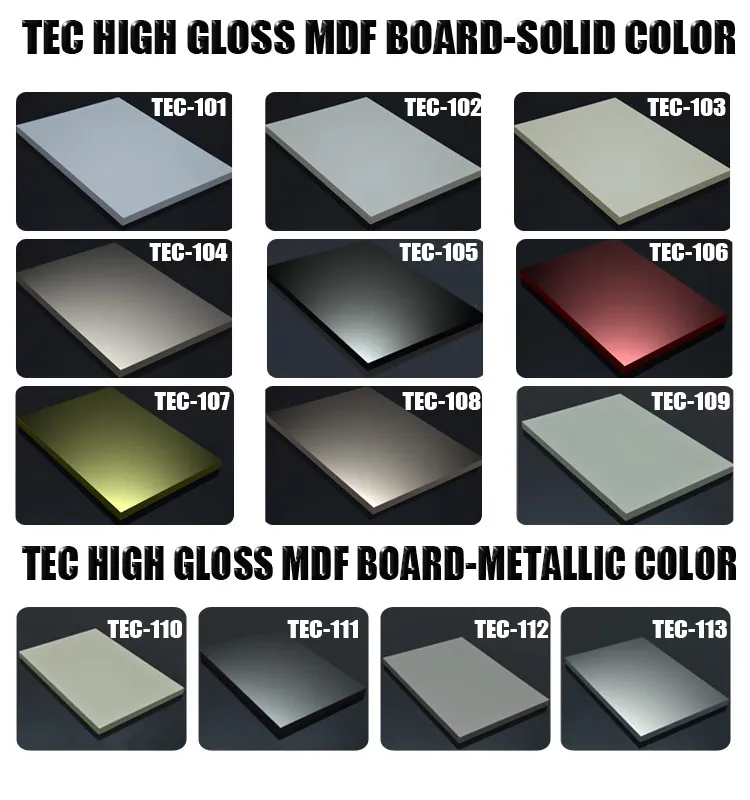

6. Rich color selection:

High-gloss EB sheet can provide a variety of color options and pattern designs to meet different decorative styles and personalized needs. Whether it is a modern minimalist style or a traditional classic style, high-gloss EB sheet can provide suitable colors and patterns to enhance the overall decorative effect.

What are the disadvantages of high-gloss EB sheet?

Disadvantages of high-gloss EB sheet: high cost, easy to show fingerprints and stains, high construction requirements, high requirements for substrates, and high brittleness.

1. High cost: Due to the complex production process of high-gloss EB sheets, high equipment investment and technical requirements, its production cost is higher than that of ordinary sheets. This leads to a high market price of high-gloss EB sheets, which may be an economic burden for consumers and projects with limited budgets.

2. Easy to show fingerprints and stains: The surface of high-gloss EB sheets is smooth and easy to show fingerprints and stains, especially in high-frequency contact areas. Although this will not affect the performance of the sheet, it will affect its aesthetics and require frequent cleaning and maintenance.

3. High construction requirements: The installation and construction requirements of high-gloss EB sheets are high, requiring professional construction teams and tools. The sheets need to be handled carefully during cutting and installation to avoid surface scratches and damage. In addition, the thermal expansion and contraction characteristics of the sheets need to be considered during the construction process to ensure stability and aesthetics after installation.

4. High requirements for substrates: High-gloss EB sheets have high requirements for the flatness and adhesion of the substrate. If the substrate is uneven or the adhesion is insufficient, it may affect the installation effect and service life of the sheet. Therefore, when using high-gloss EB sheets, it is necessary to select a substrate of good quality and ensure that the surface of the substrate is flat and clean.

5. High brittleness:

Although high-gloss EB sheets have good hardness and wear resistance, they are brittle and easily break or crack when subjected to strong impact or bending. Therefore, they need to be handled carefully during use and transportation to avoid severe collisions and bending.

What are the application areas of high-gloss EB sheets?

Although high-gloss EB sheets have some disadvantages, their excellent performance has made them widely used in many fields.

1. Interior decoration:

High-gloss EB sheets are widely used in interior decoration, such as walls, ceilings and furniture. Its high gloss and rich color selection can significantly enhance the decorative effect and create a modern and fashionable space atmosphere.

2. Furniture manufacturing:

In the field of furniture manufacturing, high-gloss EB sheets are often used to make cabinets, wardrobes, bookcases, tables and chairs. Its wear resistance and chemical corrosion resistance ensure the durability and beauty of furniture in daily use.

3. Advertising display:

The high gloss and good printing performance of high-gloss EB sheets make them an ideal choice for advertising display materials. They can be used to make billboards, display racks and light box panels, etc., providing excellent visual effects and durability.

4. Commercial space:

In commercial spaces, high-gloss EB sheets are widely used in places such as shops, hotels and office buildings. Its high-end appearance and good performance enhance the overall image and grade of commercial spaces.

Conclusion

High-gloss EB sheets have shown strong application potential in many fields due to their excellent performance and outstanding visual effects. Although they have disadvantages such as high cost, easy fingerprints and stains, these problems can be effectively solved through reasonable use and maintenance.

In the future, with the continuous innovation of technology and the diversification of market demand, high-gloss EB sheets will continue to grow and become an important part of the decorative materials market.