- Home

- >

- News

- >

- decorative board

- >

decorative board

2023-09-22 15:30

DECORATIVE BOARDS

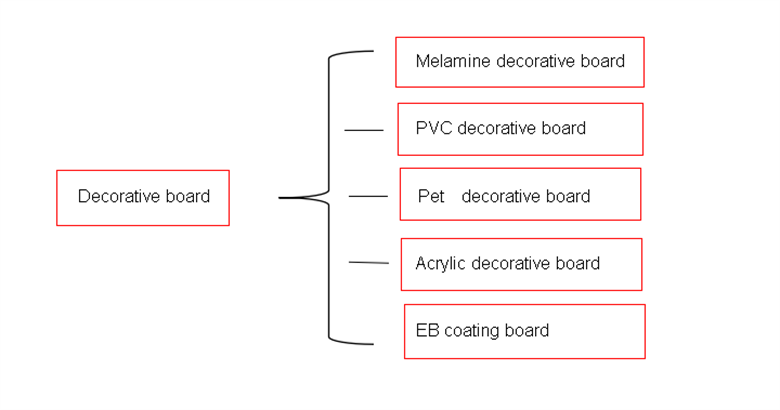

The commonly used decorative boards in home decoration include: melamine board , PVC laminated board, PET decorative board, acrylic decorative board, and EB decorative board.

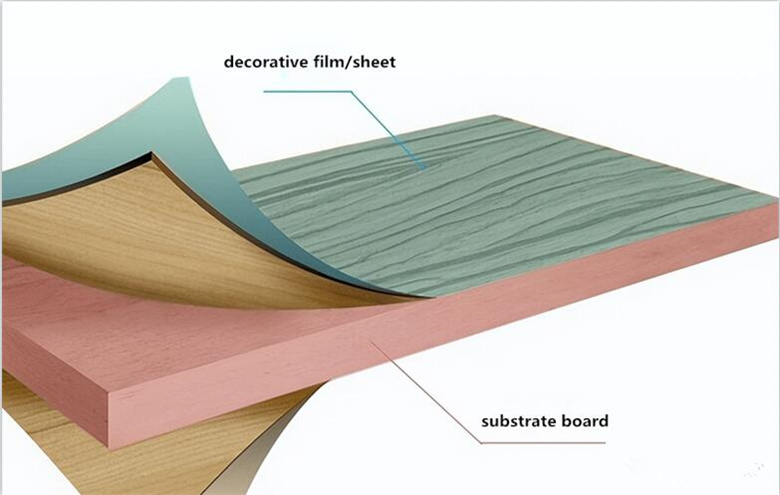

Structure of decorative boards

1.melamine decorative board:

Melamine decorative panel is a type of board made of melamine paper as the veneer material and applied to the board under high temperature and pressure. It is commonly used in furniture manufacturing, flooring, wall panels, and other indoor decoration fields.

2. PVC decorative board

PVC decorative board is a type of decorative board made of PVC material and coated with hot melt adhesive on the surface. It is commonly used in furniture manufacturing, interior decoration, wall panels, suspended ceilings, and other fields.

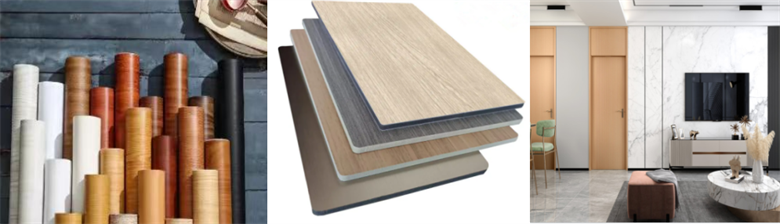

3. PET film decorative board

PET decorative board refers to a type of decorative panel made by flat pasting PET film/sheet onto various substrates through a flat pasting device. It is composed of two materials: PET film/sheet+substrate. PET is an environmentally friendly material, also known as polyethylene terephthalate plastic. The substrate can be: multi-layer board, particle board, medium fiber board, European pine board, etc. PET decorative panels are commonly used in fields such as furniture manufacturing, interior decoration, commercial display, and decoration.

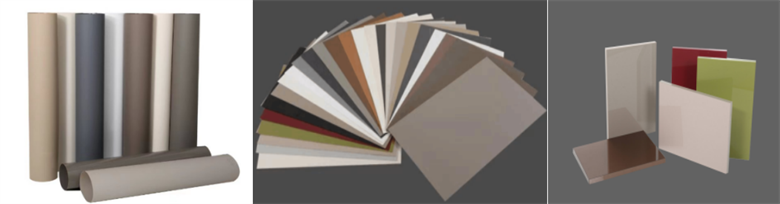

4. Acrylic decorative board

Acrylic decorative board is a decorative panel made of acrylic (PMMA) as the veneer material. Acrylic decorative panels are commonly used in fields such as furniture manufacturing, interior decoration, commercial display, and decoration.

5. EB decorative board

EB decorative board are mainly divided into two categories: one is to directly apply EB treatment to the board, and the other is to apply EB film to the board through equipment, known as EB decorative panels. EB is the English abbreviation for electron beam. EB electron beam refers to the electron beam generated by the acceleration of electrons in a high-voltage electric field. It is an energy carrier with ultra-high energy, capable of instantaneous solidification in 5 milliseconds, with an excellent curing degree of 100%, and without any harmful substance emissions. At the same time, EB electron beam curing technology, due to its ability to improve material performance and provide unparalleled physical and chemical properties, is currently the most efficient, high-quality, and clean coating and curing technology known. It was first applied to high-end fields such as aerospace and military industry, currency printing, and now it is applied to the sheet metal industry, comprehensively improving the functionality of the sheet metal and making people's home environment healthier and more environmentally friendly.

Advantages of EB decorative board

The performance advantages of EB decorative board mainly include "soft touch, extremely matte, anti fingerprint, and repairable".

Good weather resistance: The EB decorative board is weather resistant, sun resistant, and resistant to yellowing, with no discoloration for 10 years.

Resistant to dirt and easy to clean: resistant to grease, dirt, graffiti, and easy to clean.

Wear and scratch resistance: Wear and scratch resistance, high hardness, micro scratches can be hot repaired, EB cured coating, due to its strong tensile strength and high fracture elongation, good softness and elasticity, has stronger heat repair performance.

Good chemical properties: acid and alkali resistant, no formaldehyde release, food grade and environmentally friendly material,

PS: Zhihua Group has been specializing in home decoration materials for 25 years, mainly producing products such as EB SINAI decorative film/film, PETG film/sheet, acrylic sheet, UV board, PET board, EB board, acrylic MDF board , and matching color edge banding .

Welcome inquiry: 0086-18676549165, email: dayipetg@163.com.