How many years can HDF-HMR board be used?

2024-07-11 15:30

HDF-HMR board (High Density Fiberboard - High Moisture Resistant) has become a popular material widely used in environments such as kitchens, bathrooms and floors due to its excellent moisture resistance and high strength.

However, when consumers choose this new type of board, they often ask a key question: How many years can HDF-HMR board be used? This article will explore this issue in detail from multiple angles and analyze the service life of HDF-HMR board and its influencing factors.

Basic characteristics of HDF-HMR board

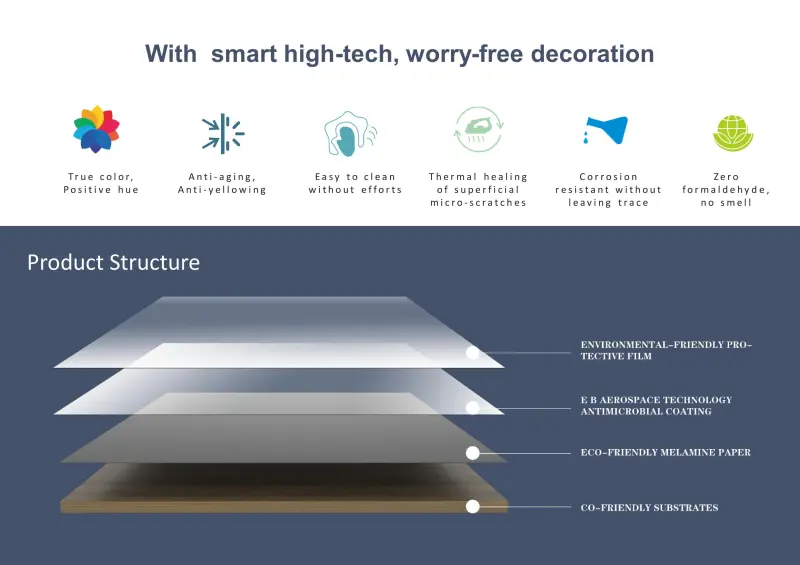

HDF-HMR board, namely High Density Fiberboard - High Moisture Resistant, is a high-performance board made on the basis of traditional medium-density fiberboard (MDF) through high temperature and high pressure process and adding moisture-proof agent. Its density is usually between 800-1000kg/m³ and has the following characteristics:

1. High density and high strength: HDF-HMR board has higher density and strength, and is suitable for application scenarios that need to withstand larger loads.

2. Excellent moisture-proof performance: Special moisture-proof agents are added to make HDF-HMR boards stable in humid environments and not easy to absorb moisture and expand.

What is the service life of HDF-HMR boards?

The service life of HDF-HMR boards is affected by many factors, including the characteristics of the material itself, production process, use environment and maintenance. Taking these factors into consideration, the service life of HDF-HMR boards can generally reach 10-20 years, or even longer.

1. Material properties:

The high density and high strength of HDF-HMR boards make them show good durability during use. Compared with ordinary medium-density fiberboard (MDF) and particleboard, HDF-HMR boards perform particularly well in high humidity environments, are not easy to absorb moisture and expand, and maintain stable physical properties. These characteristics provide a solid foundation for the long-term use of HDF-HMR boards.

2. Production process:

The production process of HDF-HMR boards has a direct impact on their service life. High-quality HDF-HMR boards use advanced manufacturing processes and strict quality control during the production process, such as high-temperature and high-pressure molding and the addition of high-efficiency moisture-proof agents, which ensure the high density and strength of the boards. In addition, the use of low-formaldehyde adhesives also improves the environmental performance and durability of the boards.

3. Use environment:

The use environment of HDF-HMR boards has a great impact on their lifespan. In extreme environments such as humidity and high temperature, even HDF-HMR boards need special attention to protection. For high-humidity environments such as kitchens and bathrooms, the moisture-proof performance of HDF-HMR boards can effectively extend their service life. However, in extreme environments, such as long-term exposure to direct sunlight or high temperatures, the boards may accelerate aging and affect their service life.

4. Maintenance:

Regular maintenance is an important measure to extend the service life of HDF-HMR boards. Timely cleaning, avoiding long-term retention of water stains, regular inspection and repair of surface damage, etc., all help to keep the boards in good condition. In addition, proper surface treatment, such as painting and filming, can also increase the durability and aesthetics of HDF-HMR boards.

What is the service life of HDF-HMR boards in different applications?

In order to better understand the service life of HDF-HMR boards, we will conduct a specific analysis from four aspects: kitchen, bathroom, floor and other high humidity environments.

1. Kitchen:

In the kitchen, the cabinets and countertops are used frequently, the environmental humidity is high, and the erosion of oil smoke and water stains is also serious. High-quality HDF-HMR boards perform well in this environment, and their moisture resistance, stain resistance and wear resistance are relatively excellent. With proper maintenance and care, the service life of HDF-HMR boards in the kitchen can generally reach 15-20 years.

2. Bathroom:

The bathroom environment is high in humidity and is often exposed to water vapor and water droplets. HDF-HMR boards are widely used in bathrooms, such as bathroom cabinets, storage cabinets, etc. Due to its excellent moisture resistance and high density, HDF-HMR boards in bathrooms usually have a service life of 10-15 years with proper maintenance.

3. Floor:

HDF-HMR boards are also commonly used as substrates for composite flooring and laminate flooring. In floor applications, HDF-HMR boards need to withstand large loads and frequent trampling. The high density and high strength characteristics enable them to maintain good physical properties for a long time. Under normal use and regular maintenance, the service life of HDF-HMR boards in floors is generally 15-20 years.

4. Other high humidity environments:

HDF-HMR boards are also suitable for decoration and furniture manufacturing in humid environments such as basements and balconies. These environments have high requirements for the moisture resistance of the boards, and HDF-HMR boards can be used for a long time in these environments due to their excellent moisture resistance and high strength. The service life is usually between 10-20 years, depending on the use environment and maintenance.

Conclusion

As a new type of high-density and high-moisture-proof board, HDF-HMR board has shown broad application prospects in the fields of home decoration and furniture manufacturing due to its excellent moisture resistance, high strength and environmental protection characteristics.

Although its service life is affected by many factors, by selecting high-quality products and performing proper maintenance, HDF-HMR boards can be used for a long time in high humidity environments, with a service life of more than 20 years.