How many years is the service life of UV MDF board?

2024-07-17 15:30

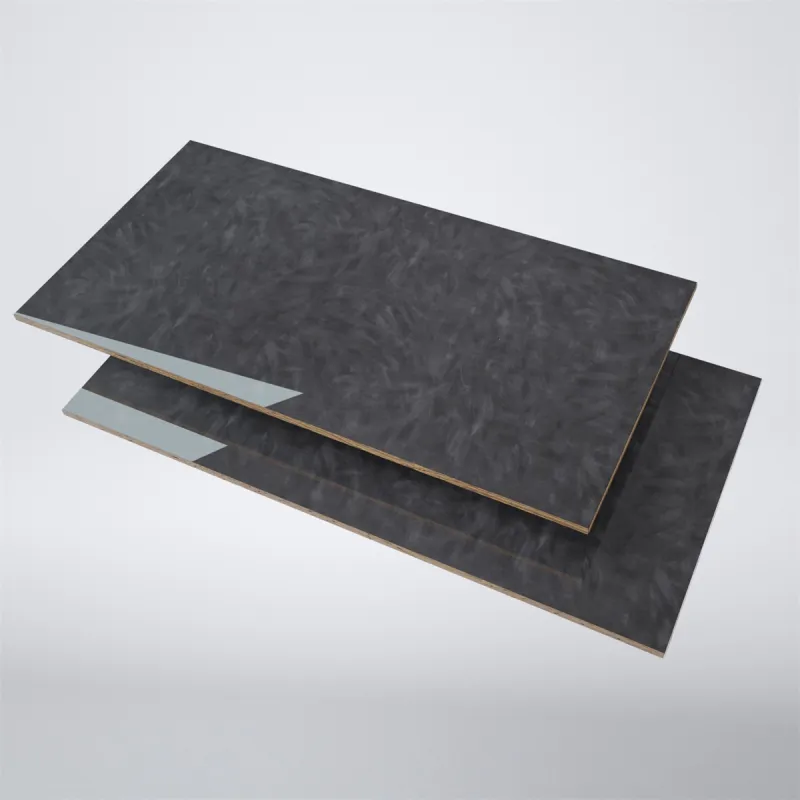

As a medium-density fiberboard treated by UV curing process, UV MDF board is gradually favored by consumers and furniture manufacturers because of its high gloss, strong wear resistance and environmental protection. Many consumers have doubts about the service life of UV MDF board.

This article will analyze the composition, production process, usage scenarios and influencing factors of UV MDF board in detail to explore its actual service life.

What is UV MDF board?

UV MDF board is a board that is UV-cured on the surface of medium-density fiberboard (MDF board). MDF board is made of wood fiber and synthetic resin pressed under high temperature and high pressure, while UV treatment refers to coating a layer of UV coating on the surface of MDF board and curing it quickly through ultraviolet light.

What is the production process of UV MDF board?

The production process of UV MDF board includes the steps of substrate production, surface treatment, coating UV coating and UV curing:

● Substrate production: First, produce MDF board that meets quality standards to ensure that its surface is smooth and the density is uniform.

● Surface treatment: Sand and clean the surface of the MDF board to ensure that the paint can adhere evenly.

● Apply UV paint: Apply a layer of UV paint evenly on the surface of the MDF board.

● UV curing: The paint is quickly cured by ultraviolet light to form a protective layer with high hardness and good gloss.

What are the characteristics of UV MDF board?

Characteristics of UV MDF board: high gloss, strong wear resistance, good environmental protection, and easy to clean.

● High gloss: The UV coating has high gloss and can present a mirror effect, making the surface of the board more beautiful.

● Strong wear resistance: The UV coating has high hardness and good wear resistance, which can effectively resist scratches and wear in daily use.

● Good environmental protection: UV coating does not contain organic solvents, and no harmful substances will be released during the curing process, which meets environmental protection requirements.

● Easy to clean: The surface of UV MDF board is smooth, not easy to be stained, and easy to clean and maintain in daily life.

What are the application areas of UV MDF board?

UV MDF boards are widely used in various home and commercial decoration scenarios, including: furniture manufacturing, interior decoration, commercial display, etc.

● Furniture manufacturing: used to make cabinets, wardrobes, bookshelves, tables and chairs and other furniture to enhance the appearance and durability of furniture.

● Interior decoration: used for wall, ceiling, door panels and other decorations to meet the decoration needs of different styles.

● Commercial display: used for display cabinets, exhibition stands, etc. in shopping malls, exhibitions and other places, which are both beautiful and practical.

What are the factors affecting the service life of UV MDF boards?

The factors affecting the service life of UV MDF boards are: raw material quality, production process, use environment, maintenance.

1. Raw material quality

● MDF substrate quality: High-quality MDF boards have uniform density and good mechanical properties, which can provide a solid foundation. Poor-quality MDF boards may have problems such as uneven density and internal defects, which affect the service life.

● UV coating quality: High-quality UV coatings have higher hardness and wear resistance, and can provide longer-lasting protection. Poor-quality coatings may have problems such as peeling and fading.

2. Production process

The production process of UV MDF board directly affects its quality and service life. Strict control of each process flow, including sanding of substrate, uniform coating, time and intensity of UV curing, etc., can improve the overall performance and service life of the board.

3. Use environment

The use environment of UV MDF board has an important impact on its life. A dry and well-ventilated indoor environment helps to extend the service life of the board, while high humidity, high temperature or frequent contact with water vapor may accelerate the aging and damage of the board.

4. Maintenance

Reasonable maintenance can significantly extend the service life of UV MDF board. Regular cleaning, avoiding scratches from sharp objects, and timely handling of surface stains and water stains are all important measures to extend the service life of the board.

Analysis of the service life of UV MDF board

1. Manufacturer's shelf life

Most manufacturers usually provide a shelf life of 5-10 years for UV MDF boards, depending on the product quality and the use environment. The manufacturer's shelf life is mainly a performance guarantee for the product under normal use. After the shelf life, the performance of the board may gradually decline.

2. Actual service life

According to market research and actual usage, the actual service life of high-quality UV MDF boards can usually reach 15-20 years or even longer under normal use and reasonable maintenance. The specific service life is also affected by the following factors:

● Daily use frequency: Frequently used furniture and decorative materials wear out faster and have a relatively short service life.

● Usage scenario: In an environment with high humidity, high temperature or frequent contact with water vapor, the service life of UV MDF boards may be affected to a certain extent.

● Maintenance: Regular cleaning, reasonable use and maintenance can effectively extend the service life of UV MDF boards.

Consumer selection suggestions

1. Pay attention to environmental certification

When choosing UV MDF boards, consumers should pay attention to the environmental certification marks of the products, such as EPA, CARB, FSC, etc. Choose low-formaldehyde or formaldehyde-free products that have passed environmental certification to ensure the health and safety of the home environment.

2. Choose regular brands

Give priority to UV MDF board products produced by well-known brands and regular manufacturers. These brands usually have stricter quality control and higher product standards, and can provide better after-sales service and quality assurance.

3. Choose according to needs

Choose UV MDF board products with appropriate specifications and performance according to specific usage scenarios and needs. In high humidity or high wear environments, such as kitchens and bathrooms, it is recommended to choose UV MDF boards with better water resistance and wear resistance.

Conclusion

As an environmentally friendly, high-performance and beautiful new material, UV MDF boards have broad application prospects in furniture manufacturing and interior decoration. Through reasonable selection and use, UV MDF boards can bring higher decorative effects and usage experience to the home environment.