HOW TO IDENTIFY TRUE AND FALSE EB FOUR RESISTANCE FILMS : LOOK, SMELL, TOUCH,SHINE

2023-05-10 15:30

HOW TO IDENTIFY TRUE AND FALSE EB FOUR RESISTANCE FILMS : LOOK, SMELL, TOUCH,SHINE

Why is the market vigorously promoting EB technology now? Good technology is applied to industry and empowered can it truly have market value.

In the past few years, electron beam technology has rapidly evolved in the field of material surface treatment, making EB curing a more efficient and environmentally friendly alternative to traditional curing methods.

For example, the EB four resistant film launched by Guangdong DAEI New Materials Co., Ltd. After EB treatment, the surface of the material has strong hardness, resistance to yellowing, pollution, acid and alkali resistance, scratch resistance, heat repair and other properties. This technology is not only high-energy, but also safe and reliable. With aerospace grade material technology and food grade safety technology, EB has become a highly potential process in the field of decorative materials.

The brilliance and popularity of EB technology have attracted the attention of many manufacturers, but the expensive cost of equipment acquisition and the insufficient level of technology application have deterred them.

So how to distinguish the authenticity of EB four resistant films?

In the laboratory, a comprehensive "physical examination" of the product makes it easy to distinguish between EB film and other products. What if there is no laboratory or it is inconvenient for experimental testing?

Don't worry! EB film has obvious advantages over other technology products in terms of physical and chemical properties such as scratch resistance, aging resistance, and dirt resistance. Therefore, even when leaving the laboratory, we can easily distinguish between true and false!!

Remember the simple 4-word formula to quickly determine if it is an EB four film resistant plate, which is " look, smell, touch, and sunshine"

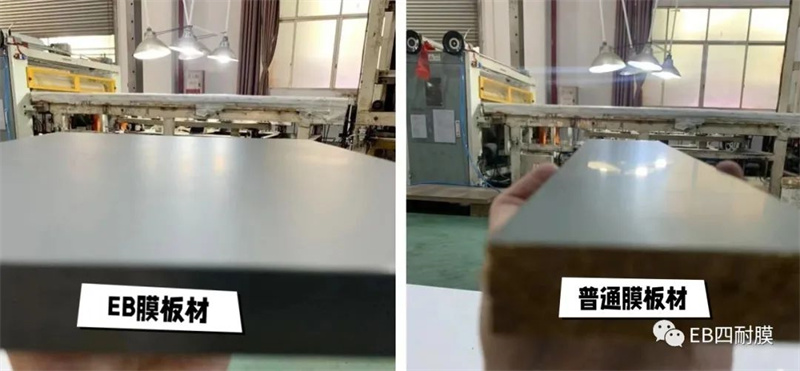

Observing the board surface from a small angle towards the light source (light or window), if it is a completely matte EB film board, the light source cannot see the outline, only a bright spot, while ordinary skin matte film boards can clearly see the outline of the light source.

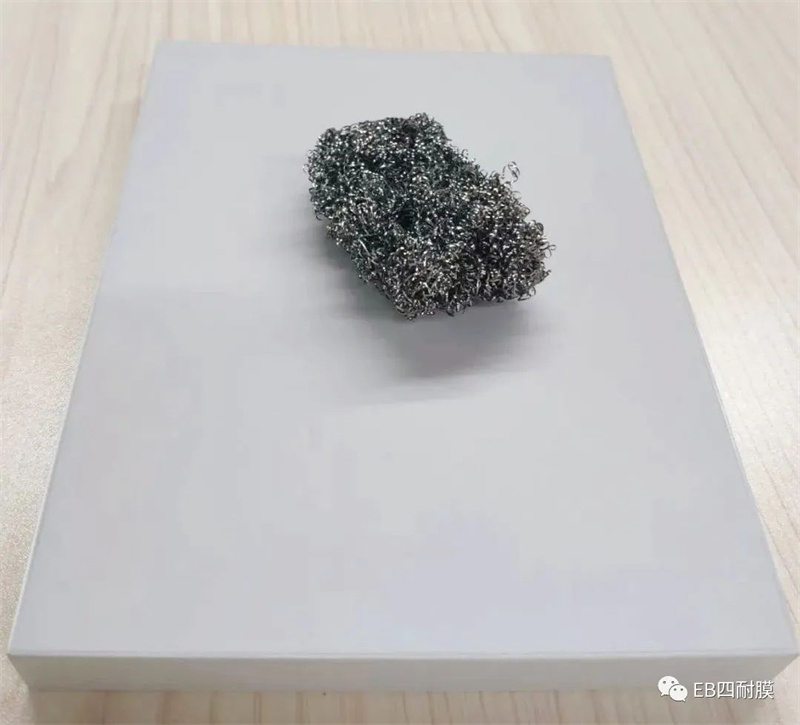

Use steel velvet or steel wire balls to lightly polish the surface of the EB membrane board, damaging the structure of the surface paint. Then, close your nose to smell it, and the EB membrane board is completely odorless.

Because EB four resistant film adopts electron beam curing technology, the extremely high energy makes the curing reaction close to 100%, and there is no initiator added, truly achieving complete health and environmental protection.

Gently stroke the board surface with your hand to feel the touch of the board surface. The EB four resistant film board has a unique matte feel, which is thicker than ordinary skin matte boards in terms of touch. It is not that sticky feel, but it is also the same smooth and skin friendly, with some details being discussed in detail.

This unique touch is unique to EB, just like some imported brand EB products. If the EB four resistant film board is placed together with a regular board, you can definitely distinguish it immediately through touch.

Place the EB film veneer test board together with a known UV board of the same color/imported PET film board/domestic PET film board, cover a small portion and expose a portion, and expose it to sunlight for natural exposure. After a period of exposure, observe the test board when the comparison sample UV board/imported PET film board/domestic PET film board shows significant yellowing. If the yellowing of the test board is significantly better than other decorative panels, It can be basically determined that this test board is an EB membrane board.

Remember to use light colored boards for this test, so that changes in the surface coating are not easily covered by the background color.

Among various physical and chemical performance indicators, the yellowing value is relatively easy to test, and the national standard is to use professional equipment to test the color difference value after 168 hours of enhanced ultraviolet radiation on the board surface. As shown in the figure, we conducted ultraviolet light testing on four types of boards.

By comparing the pictures, we can find that there is a significant yellowing phenomenon in the white UV board, imported PET board, and domestic PET board. The zhihua EB four resistant film is unique in its existence, and color changes are almost invisible to the naked eye. This indicates that zhihua EB four resistant film not only has excellent weather and chemical resistance, but also has excellent appearance performance, making it the best choice for your decoration materials.