Introduction to Furniture Impregnated Film Paper Veneer

2023-12-27 15:30

Introduction to Furniture Impregnated Film Paper Veneer

With the increasing personalized needs of consumers and the positioning of high-end products for the quality requirements of artificial boards, the production process of impregnated film veneer artificial boards is also constantly improving. In order to meet the different needs of different substrates for veneers, domestic manufacturers of impregnated film paper veneer artificial boards continuously improve their production process through technological research and development.

The processing technology of impregnated film paper veneer artificial board varies depending on the type of substrate. Among them, the preparation process of impregnated adhesive film paper veneer artificial board using particleboard and fiberboard as substrates is to directly press the impregnated adhesive film paper onto the substrate.

The preparation process of impregnated film paper decorative panels based on blockboard and plywood can be divided into "primary lamination method" and "secondary lamination method", as shown in the following figure. Among them, in the "one-time lamination method", the substrate is first pressed and laminated with the veneer, and then pressed onto the impregnated film paper. In this process, the impregnated film paper only goes through one press.

The "secondary lamination method" is to first heat press the impregnated film paper onto the veneer, and then press the composite impregnated film paper and the veneer together onto the substrate. This process involves two hot presses of the impregnated film paper, which is called the secondary lamination method.

1: There are problems with impregnated film veneer artificial boards

(1) Quality issues with impregnated film paper

The use of impregnated film paper as a decorative material is a key factor in determining the quality of impregnated film paper used for decorative artificial boards. The quality of impregnated film paper is affected by factors such as the permeability of the original paper, the amount of impregnated film paper, drying temperature, residual volatile matter content, pre solidification degree, and storage conditions of impregnated film paper.

At present, some companies in China that produce impregnated film paper are unable to achieve consistent quality in preparing the same type of impregnated film paper in different batches and times. This problem will affect the lamination effect of the same product and increase the production error rate. Home furnishings made from impregnated film veneer artificial boards may experience surface fading during use, which affects their appearance.

The main reason for the surface fading of artificial boards is the poor light fastness performance of the impregnated film paper used. Currently, the light fastness level of decorative artificial boards in China is between 3 and 4 levels.

At present, manufacturers of impregnated film paper choose low weight paper and add a certain amount of titanium dioxide to improve the covering power and whiteness of the paper. However, adding too much titanium dioxide can make the paper too brittle, causing the impregnated film paper to crack during transportation and pressing.

(2) Appearance question of impregnated film paper

The common appearance quality defects of impregnated film paper veneer artificial boards include dry and wet spots, layering, bubbling, surface indentation, scratches, missing paper, edge defects, bottom penetration, pollution, color mismatch, paper tearing, etc.

The uneven material and uneven surface of the artificial board substrate can ultimately lead to problems such as dry spots and indentations on the surface of the impregnated adhesive paper veneer artificial board. Enterprises producing impregnated film paper veneer artificial boards in the southern region of the Yangtze River in China are prone to surface quality problems such as wet spots during the lamination process due to high air humidity in the southern region.

Due to the climate differences between the wet south and dry north in China, wood, as an anisotropic material, moves water quickly and undergoes uneven shrinkage and swelling under external conditions, resulting in cracking and deformation of the wood. Ecological boards based on solid wood core boards of plywood and block board are prone to surface cracking due to poor dimensional stability of the substrate.

2: Suggestions for impregnation film veneer artificial board

(1) Developing new technologies for producing impregnated film paper

Enterprises should pay attention to technological innovation and usage based on personalized consumer needs, and improve the product quality and usage effect of impregnated film paper. For example, using digital printing technology to achieve personalized graphic and text production of decorative paper in small batches, digital printing technology can also be combined with the latest polymer photopolymerization technology to achieve decorative relief effects.

The use of impregnation film paper synchronous pattern matching technology utilizes a high-definition photography system and precise positioning equipment to completely print the carved texture on the steel plate onto the decorative base paper, so that the printed pattern on the decorative base paper coincides with the texture of the steel plate. This can greatly meet the needs of consumers for furniture, floors, and door panels with high-quality surface decoration effects with solid wood texture.

(2) Increase product functionality requirements

Based on the new situation and policies, as the main material for producing home products in China, impregnated film paper veneer artificial board should not only achieve style innovation in decorative appearance, but also pay attention to market demand and dynamics, actively cooperate with research institutes and universities, and attach importance to the research and development of functional products, such as flame retardant board, anti-corrosion and mold proof board, antibacterial board, moisture-proof board, and other functional boards.

(3) Improve product quality

Impregnated film paper veneer artificial board has the advantages of efficient processing technology and high cost-effectiveness, and has become the mainstream of veneer artificial board. To promote scientific development and build a beautiful China, enterprises producing impregnated film paper veneer artificial boards should pay comprehensive attention to the environmental impact of their products, such as formaldehyde, TVOC emissions, odor, etc. Strictly control the impact of producing impregnated film paper veneer artificial boards on environmental quality, promote the upgrading and transformation of production equipment technology, reduce pollution emissions, and protect the ecological environment. Continuously improving the durability, optical rotation resistance, and decorative properties of impregnated film veneer artificial boards, achieving true sustainable development.

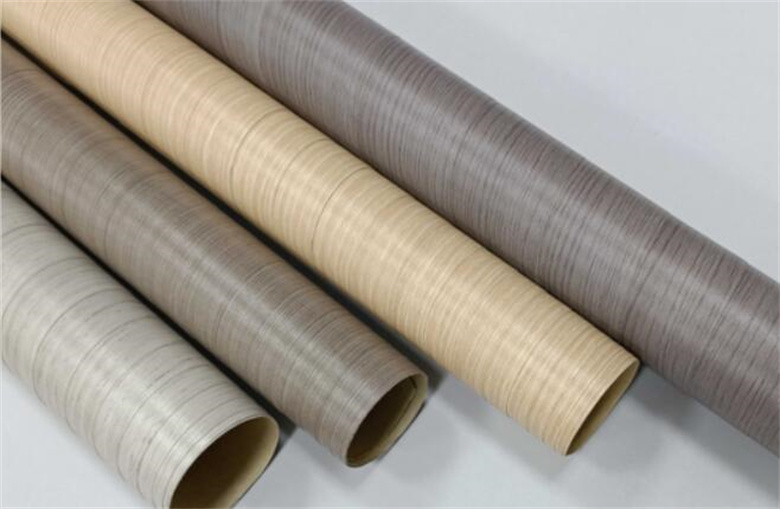

3: Recommendation for Latest Craft Decorative Paper

To further expand the sales range and increase market share of impregnated film paper veneer artificial boards, it is necessary to further strengthen the quality and performance of such products, break through the defects caused by the raw materials of impregnated film paper veneer artificial boards, and continuously optimize the processing technology. Therefore, in response to the research and development of improving the product quality of impregnated film paper veneer artificial boards, Zhihua Group has launched the latest EB SINAI paper, which perfectly combines advantages such as wear resistance, scratch resistance, aging resistance, weather resistance, acid and alkali resistance, yellowing resistance, and oil pollution resistance. We welcome customers to inquire and take samples!