Is MDF a furniture board?

2024-07-08 15:30

In modern furniture manufacturing and interior decoration, the choice of materials is crucial and directly affects the beauty, durability and environmental performance of furniture. Medium-density fiberboard (MDF board) is widely used in the furniture manufacturing industry because of its flat and smooth surface, good processing performance and relatively low cost.

This article will explore in depth whether MDF board is a suitable furniture board, and conduct a detailed analysis from many aspects such as its basic characteristics, application scenarios, advantages and disadvantages.

What is MDF board?

1. Definition of MDF board:

MDF board, or medium-density fiberboard, is a man-made board made by combining wood fibers with synthetic resins and pressing them under high temperature and high pressure. Its density is usually between 600-800 kg/m3, which is between particleboard and high-density fiberboard (HDF board).

2. Production process of MDF board:

The production process of MDF board includes steps such as fiber separation, drying, gluing, molding and hot pressing. First, the wood is broken down into fine wood fibers by mechanical or chemical methods, and then the fibers are dried. Next, the dried wood fiber is mixed with synthetic resin, and after the molding and hot pressing process, an MDF board with uniform density and good mechanical properties is finally formed.

Application of MDF board in furniture manufacturing

1. Wide application in furniture manufacturing:

MDF board is widely used in the manufacture of various types of furniture due to its excellent processing performance and cost advantages. Specific applications include:

● Cabinets: MDF boards are often used to make cabinet door panels and cabinet bodies. Its flat surface is easy to spray paint and film, and can present a variety of appearance effects.

● Bookshelves and storage cabinets: Due to the good strength and stability of MDF boards, they are often used to make bookshelves, storage cabinets and other load-bearing furniture.

● Tables and chairs: MDF boards can be used to make tabletops and chair seats, and have high durability and beauty after edge banding.

● Decorative furniture: MDF boards are easy to carve and shape, and can be used to make furniture with complex shapes and decorative effects, such as headboards, decorative cabinets, etc.

2. Surface treatment and decoration:

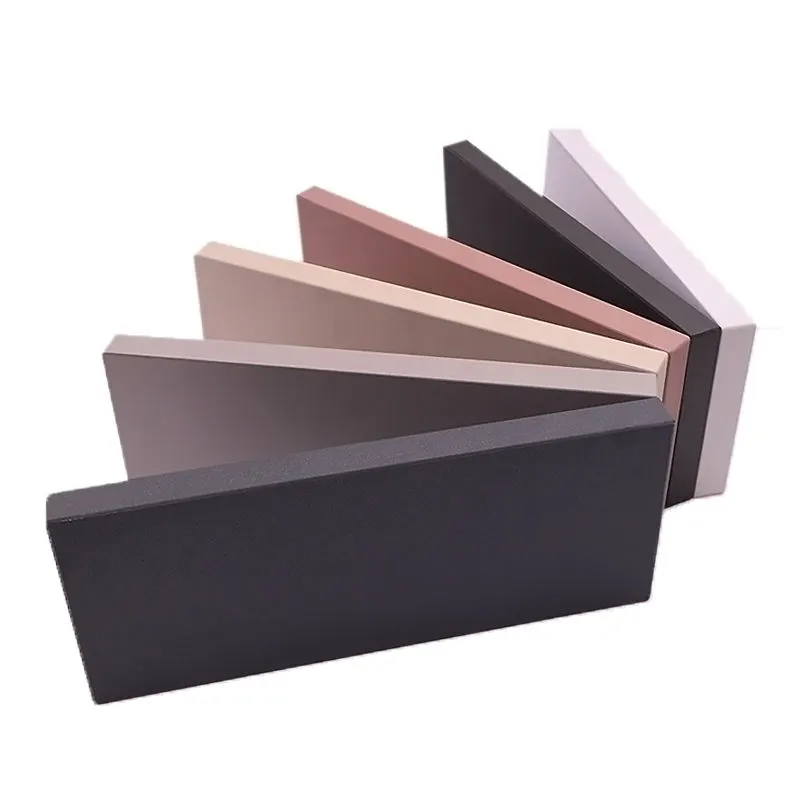

MDF board has a smooth surface and is suitable for a variety of surface treatment and decoration processes, including:

● Spray painting: MDF board is easy to spray paint, and can achieve a variety of colors and gloss effects to meet the needs of furniture of different styles.

● Film: By attaching decorative materials such as PVC film and wood grain paper, MDF board can present a variety of appearance effects, such as wood grain, stone grain, etc.

● Coating: Covering the surface of MDF board with a layer of veneer or other decorative layer can enhance its appearance and durability.

Analysis of the advantages and disadvantages of MDF board

1. Advantages:

● Superior processing performance: MDF board is easy to cut, carve, drill and other mechanical processing, and can produce various complex furniture parts.

● Smooth surface: The surface of MDF board is flat and smooth, suitable for a variety of surface treatments, and can achieve rich decorative effects.

● Low cost: Compared with solid wood and other high-end boards, MDF board has a lower production cost, is relatively cheap, and has a high cost performance.

● Good uniformity: The internal structure of MDF board is uniform, and it is not easy to have defects such as scarring and cracks, and it has good stability and consistency.

2. Disadvantages:

● Poor water resistance: MDF board has poor water resistance, and it is easy to swell and deform when exposed to humid environment for a long time. It is not suitable for high humidity places such as kitchens and bathrooms.

● Limited strength: Although MDF board has certain strength, its bending strength and impact resistance are not as good as solid wood and high-density fiberboard, and it is easy to be damaged in high-intensity use environment.

● Environmental issues: MDF board uses a large amount of synthetic resin in the production process, which may contain harmful substances such as formaldehyde. During use, MDF board may release a certain amount of formaldehyde, affecting indoor air quality. Therefore, it is particularly important to choose environmentally friendly MDF board with low formaldehyde or no formaldehyde.

Market feedback and actual case analysis

In order to have a more comprehensive understanding of the performance of MDF board in furniture manufacturing and consumer feedback, we collected some actual cases and market survey data.

1. Consumer feedback:

● Positive feedback: Most consumers are satisfied with the appearance and cost performance of MDF board furniture. MDF board furniture has a smooth surface, good decorative effect, and is relatively cheap, making it an economical choice for many families.

● Negative feedback: Some consumers are concerned about the durability and environmental performance of MDF board furniture. Especially in high humidity environments, MDF board furniture is prone to expansion and deformation. In addition, the formaldehyde release problem also makes some consumers feel uneasy.

2. Actual cases:

● Case 1: Family cabinets: A family used a large number of MDF boards to make cabinet door panels in the kitchen decoration. After a period of use, it was found that the paint film on the surface of the door panel was intact and the appearance was beautiful, but there was a slight expansion problem on the door panel near the sink.

● Case 2: Office furniture: A company purchased a batch of MDF board office desks and chairs. After a year of use, the surface of the office desk remained flat and smooth, and the seat of the office chair did not show obvious wear. The employees were satisfied with the appearance and use experience of the office furniture.

● Case 3: Children's furniture: A kindergarten used MDF boards to make a batch of children's bookshelves and lockers. In order to ensure environmental protection, low-formaldehyde environmentally friendly MDF board products were selected. After air quality testing, the formaldehyde concentration met the national standard and did not affect children's health.

Conclusion

MDF board, as a widely used board in furniture manufacturing, occupies an important position in the market with its excellent processing performance, smooth surface and relatively low cost.

Although MDF board has certain limitations in water resistance, strength and environmental protection performance, by selecting environmentally certified products and using them reasonably, MDF board can fully meet most home and decoration needs.