Is MDF board suitable for furniture manufacturing?

2024-07-03 15:30

In the modern furniture manufacturing industry, the choice of materials directly affects the quality, performance and market competitiveness of the product. As a common board, medium-density fiber board (MDF board) is widely used in furniture manufacturing and interior decoration due to its good processability and flatness.

However, is MDF board really suitable for furniture manufacturing? What are its advantages and disadvantages? This article will explore these issues in depth and provide relevant expert opinions and market feedback.

What is MDF board?

Medium-density fiber board (MDF) is a man-made board made of wood fiber through high-temperature and high-pressure processes. MDF board is usually made of waste wood, sawdust, etc. as raw materials, and is formed after grinding, pressing, drying and other processes. Its density is usually between 600-800kg/m³.

What are the characteristics of MDF board?

The main characteristics of MDF board include: smooth and flat surface, strong processability, and relatively low cost.

● Smooth and flat surface: convenient for various surface treatments, such as painting, veneer, etc.

● Strong processability: easy to cut, carve, drill and other processing operations.

● Relatively low cost: Compared with solid wood and other high-end boards, MDF boards are more affordable.

Is MDF board suitable for furniture manufacturing?

Application of MDF board in furniture manufacturing: furniture frame (cabinet, drawer, table, etc.), surface decoration (surface treatment such as spray painting, veneer, lamination, etc.), detail carving (fine carving and processing).

1. Furniture frame:

MDF board is often used in the frame structure of furniture, such as cabinet, drawer, table, etc. Due to its uniform density, stable structure, not easy to deform, it can provide solid support and long-lasting service life.

2. Surface decoration:

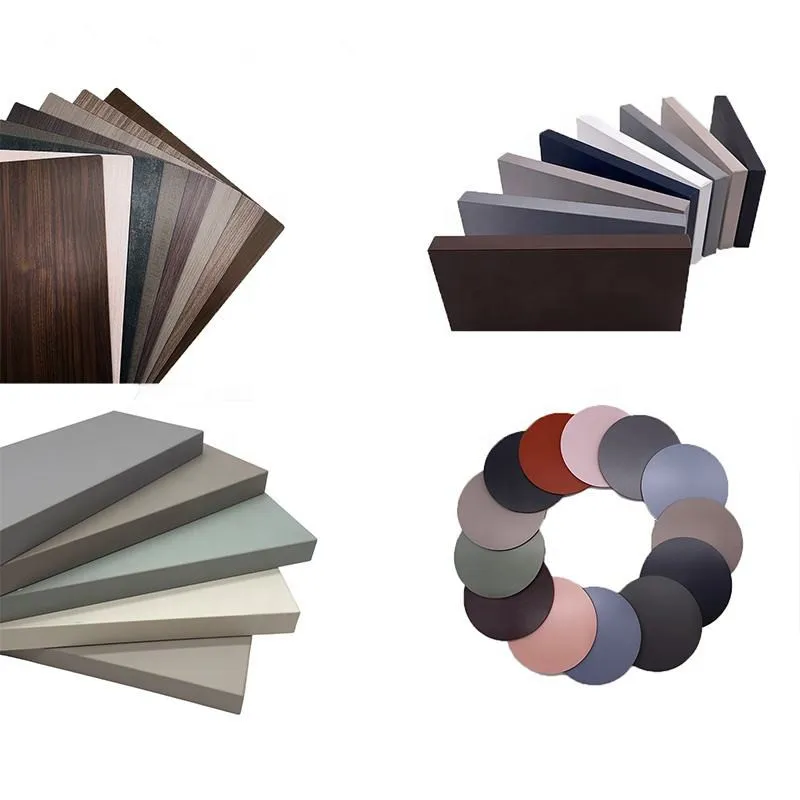

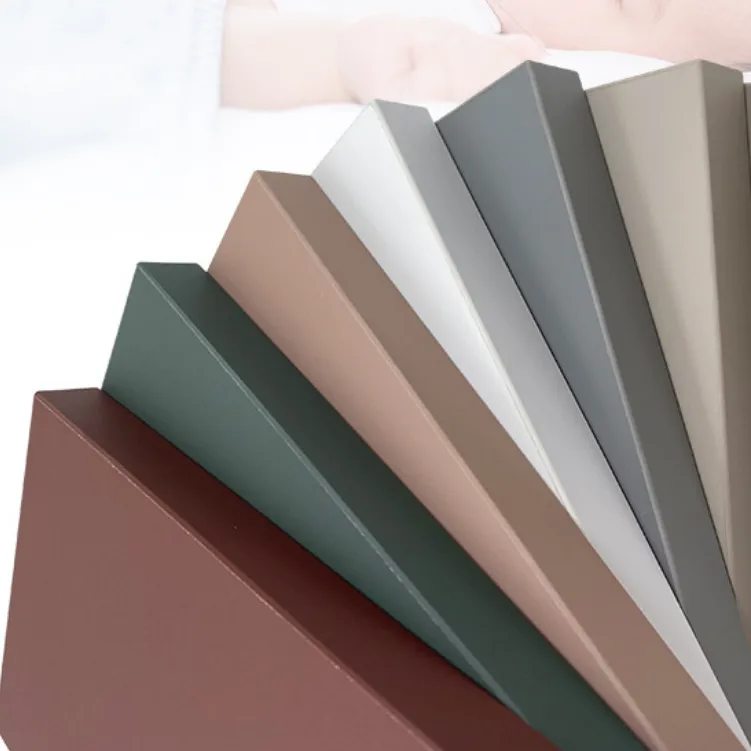

MDF board has a smooth surface and is very suitable for surface treatment such as spray painting, veneer, lamination, etc. Whether it is modern minimalist style or classic retro style, MDF board can present a variety of decorative effects through surface treatment to meet the needs of different consumers.

3. Detail carving:

Due to the uniform density and moderate hardness of MDF board, it is easy to carry out fine carving and processing. Furniture designers can carve various patterns and designs on MDF boards to enhance the artistry and beauty of furniture.

What are the advantages of MDF boards in furniture manufacturing?

Advantages of MDF boards in furniture manufacturing: good machinability (easy to cut, drill, and carve), flat and smooth surface (spray paint, veneer), stable structural performance (not prone to scarring and cracks), and high cost-effectiveness (relatively affordable).

1. Good machinability:

MDF boards are easy to cut, drill, and carve, and can meet the needs of various complex furniture designs. Its processing performance is superior, and it can achieve fine process details and improve the quality and grade of furniture.

2. Flat and smooth surface:

The surface of MDF boards is flat and smooth, which is suitable for various surface treatments. Whether it is spray painting, veneer or lamination, MDF boards can present ideal effects and enhance the beauty and decorativeness of furniture.

3. Stable structural performance:

MDF boards have uniform density and are not prone to scarring, cracks, and other problems. Its structure is stable, not easy to deform and crack, and can maintain the integrity and stability of furniture for a long time.

4. High cost-effectiveness:

Compared with solid wood and other high-end boards, MDF boards are more affordable. It is cost-effective and can reduce manufacturing costs and improve market competitiveness while ensuring the quality of furniture.

What are the disadvantages of MDF boards in furniture manufacturing?

Disadvantages of MDF boards in furniture manufacturing: poor moisture resistance (easy to absorb moisture and expand), general durability, and environmental protection performance needs to be improved.

1. Poor moisture resistance:

MDF boards have weak moisture resistance and are prone to absorb moisture and expand in high humidity environments, resulting in deformation and damage. Therefore, they are not suitable for furniture manufacturing in humid environments such as kitchens and bathrooms.

2. General durability:

Although MDF boards have good structural stability, their wear resistance and impact resistance are relatively poor. Long-term use may cause surface wear, scratches and other problems, affecting the service life and appearance of furniture.

3. Environmental protection performance needs to be improved:

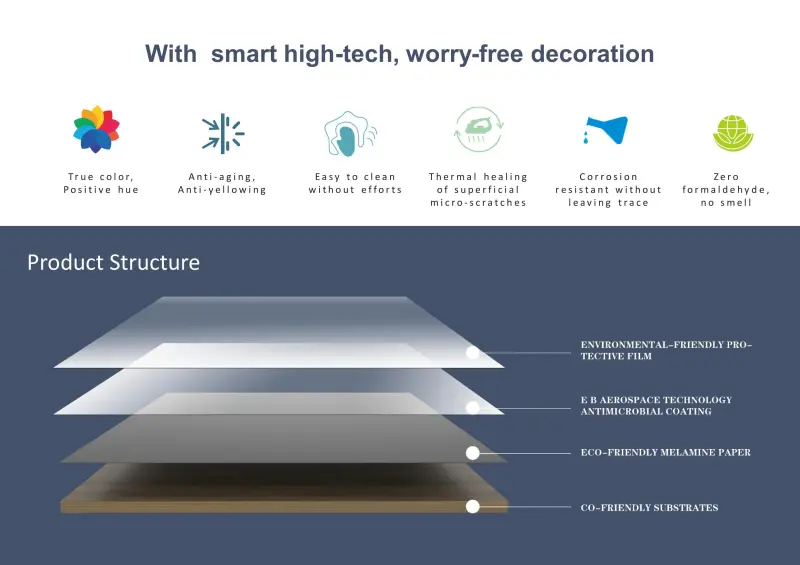

Although MDF boards use environmentally friendly adhesives in the production process, they may still release a certain amount of formaldehyde due to the limitations of their raw materials and production processes. Although the formaldehyde emission of most MDF boards meets environmental standards, there is still room for improvement in environmental performance.

Practical use case analysis of MDF boards in furniture manufacturing

In order to better understand the practical application of MDF boards in furniture manufacturing, we selected several practical cases for analysis.

Case 1: Bedroom furniture

The bedroom furniture of a family is made of MDF boards, including wardrobes, bookshelves and bedside tables. The surface of MDF boards is smooth and easy to paint, making these furniture not only beautiful but also durable. The owner said that these furniture have been in good condition for many years, and there is no obvious wear and deformation on the surface.

Case 2: Living room furniture

In the decoration of a family's living room, the designer chose MDF boards to make TV cabinets and coffee tables. The processability and decorativeness of MDF boards make these furniture coordinated with the overall style of the living room, improving the overall beauty of the home. However, due to the relatively dry environment of the living room, the moisture-proof performance of MDF boards has not been tested.

Case 3: Kitchen furniture

In the kitchen decoration of a restaurant, the owner tried to use MDF boards to make cabinets and countertops. However, due to the high humidity in the kitchen environment, the MDF board had problems of moisture absorption, expansion and deformation after a period of use, which affected the normal use of the cabinet. In the end, the owner had to replace it with HMR board with better moisture resistance.

Conclusion

As an important material in the modern home building materials market, MDF board has good processability and flatness, and is suitable for most furniture manufacturing and interior decoration. When choosing, consumers should consider the specific needs, budget and use environment.

Although MDF board has certain shortcomings in moisture resistance and durability, its aesthetics and cost-effectiveness make it have a wide range of application prospects in dry environments.