What scenarios are suitable for MDF (medium density fiber) boards?

2024-07-19 15:30

MDF (medium density fiberboard), as a widely used man-made board, is favored by the construction, furniture and decoration industries due to its unique properties and wide range of application scenarios.

This article will delve into the specific application scenarios of MDF boards and analyze its advantages and disadvantages in detail to help readers fully understand this material.

What scenarios are suitable for MDF (medium density fiber) boards?

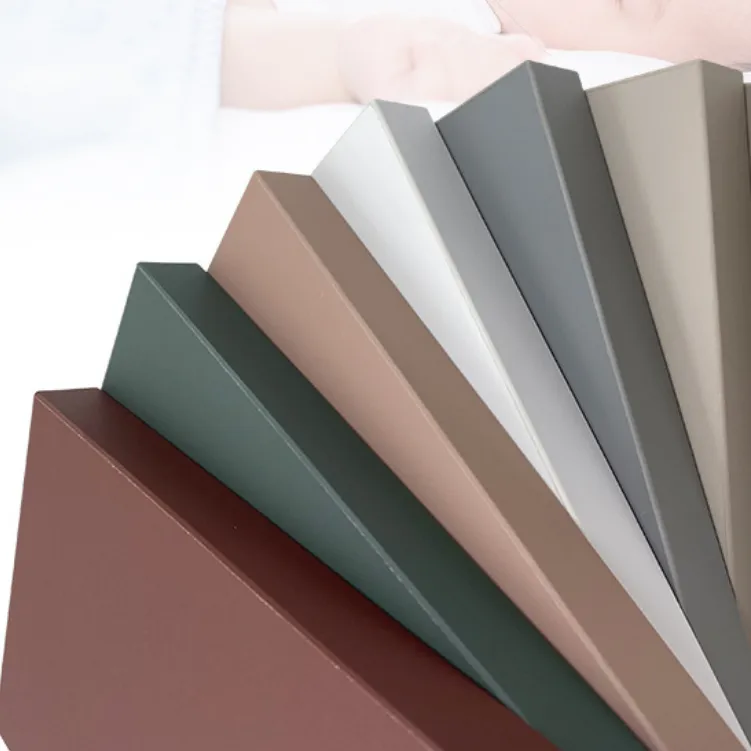

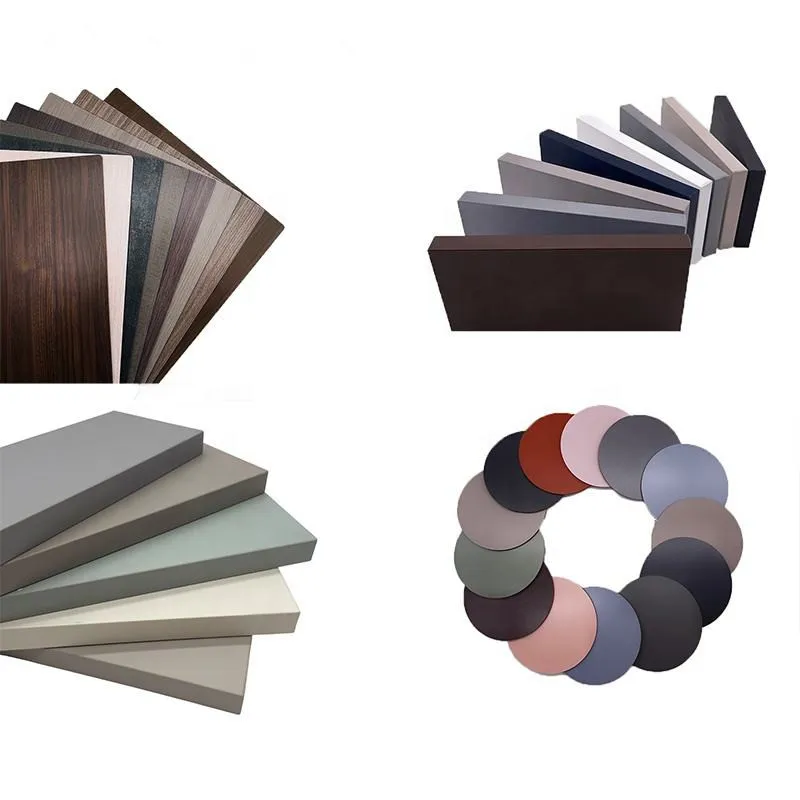

1. Furniture manufacturing: MDF boards are widely used in furniture manufacturing due to their flat and smooth surface and good processing performance. Specific applications include: cabinets and wardrobes, bookshelves and display racks, tables, chairs and beds, etc.

● Cabinets and wardrobes: MDF boards are easy to paint and veneer, and can be used to make beautiful and durable cabinets and wardrobes.

● Bookshelves and display racks: Its high strength and stability make it an ideal material for bookshelves and display racks.

● Tables, chairs and beds: MDF boards can be used to make various tables, chairs and bed frames, especially furniture that requires complex shapes and fine surface treatment.

2. Interior decoration: In the field of interior decoration, MDF boards are also widely used: wall decoration boards, ceiling materials, doors and door frames, etc.

● Wall decoration boards: MDF boards can be processed into various decorative boards for wall decoration, providing a variety of visual effects.

● Ceiling materials: Its light weight and easy processing make it an ideal choice for ceiling materials.

● Doors and door frames: MDF boards can be used to make flat, smooth and easy-to-paint doors and door frames.

3. Building materials: In the field of construction, MDF boards are also widely used: partition walls and sound insulation boards, floor substrates, etc.

● Partition walls and sound insulation boards: MDF boards have good sound insulation properties and are often used to make partition walls and sound insulation boards.

● Floor substrate: Although MDF boards are not directly used as floor surface materials, they can be used as floor substrates to provide a flat foundation for the floor.

4. Commercial display and exhibition: MDF board is also important in commercial display and exhibition because of its easy processing and surface treatment: display cabinets and booths, billboards and signboards, etc.

● Display cabinets and booths: MDF board can be used to make a variety of display cabinets and booths, suitable for various commercial display needs.

● Billboards and signboards: The flat surface and easy processing of MDF board make it an ideal material for billboards and signboards.

What are the advantages of MDF board?

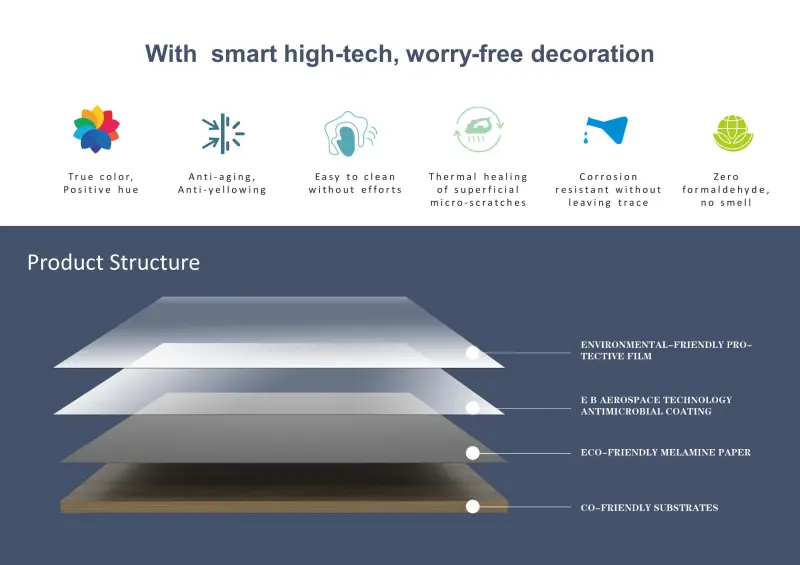

Advantages of MDF board: flat and smooth surface (suitable for painting, veneer and other surface treatments), easy processing (easy to cut, drill and mill), high strength and stability (not easy to deform and crack), environmental protection characteristics.

1. Flat and smooth surface: The surface of MDF board is very flat and smooth, suitable for painting, veneer and other surface treatments, and can achieve high-quality decorative effects. This makes MDF board popular in furniture manufacturing and interior decoration.

2. Easy to process: MDF board has uniform density and structure, easy to cut, drill and mill, and can be processed into various complex shapes and shapes. This gives designers and craftsmen greater creative freedom when making furniture and decorations.

3. Strength and stability: MDF boards have high strength and stability, are not easy to deform and crack, and are suitable for making various furniture and building materials that require structural strength. Its bending resistance is better than particleboard, and it performs better in applications that need to withstand greater pressure.

4. Environmental characteristics: MDF boards are made of wood waste and recycled materials, which reduces wood waste and conforms to the concept of sustainable development. At the same time, the adhesives used in modern MDF board production processes are also constantly improving, reducing the emission of harmful substances.

What are the disadvantages of MDF boards?

Disadvantages of MDF boards: poor waterproof performance (easy to be deformed by moisture), low impact resistance (easy to be damaged when hit by strong force), heavy weight, and relatively high cost.

1. Poor waterproof performance: MDF boards have strong water absorption, are easy to be deformed by moisture, and their waterproof performance is not as good as plywood and some high-density boards. Therefore, using MDF boards in humid environments requires additional waterproofing.

2. Low impact resistance: MDF boards have relatively low impact resistance and are easily damaged when subjected to strong impact. In applications that require high durability and impact resistance, MDF boards may not be as good as plywood and solid wood boards.

3. Heavy weight: Compared with lightweight boards such as particleboard, MDF boards have a higher density and are heavier. This may cause certain inconveniences during handling and installation, especially in the application of large furniture and decorative panels.

4. Relatively high cost: Although the price of MDF boards is lower than that of solid wood boards, its cost is relatively high compared to low-end boards such as particleboard. This may increase the overall budget of the project, especially when used on a large scale.

Conclusion

As a versatile man-made board, MDF boards have been widely used in furniture manufacturing, interior decoration and construction due to their excellent processing properties and surface quality.

Its advantages include smooth surface, easy processing, stable strength and environmental protection, which make it perform well in a variety of application scenarios. However, MDF boards also have disadvantages such as poor waterproof performance, low impact resistance, heavy weight and high cost, which need to be paid attention to during use.