Which is better, UV MDF board or PVC board?

2024-07-25 15:30

In modern home decoration and furniture manufacturing, various materials emerge in an endless stream, among which UV MDF board and PVC board are common and popular choices. Consumers often face a question when choosing materials for decoration and furniture: Which is better, UV MDF board or ordinary PVC board?

This article will analyze in detail the material characteristics, application scenarios, advantages and disadvantages, etc. to help consumers make wise choices.

What are UV MDF board and PVC board?

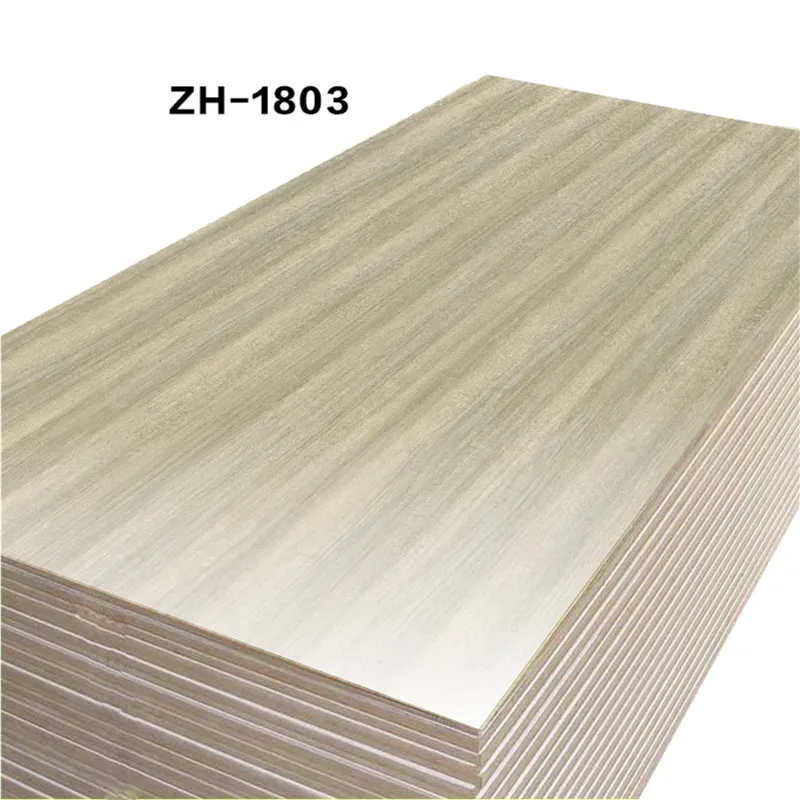

1. Definition of UV MDF board

UV MDF board is a board that is treated with ultraviolet light on the surface of medium-density fiberboard (MDF board). MDF board is made of wood fiber and synthetic resin pressed under high temperature and high pressure, while UV treatment is to apply a layer of UV coating on the surface of MDF board, and cure it quickly through ultraviolet light to form a high-gloss, wear-resistant surface.

2. Definition of ordinary PVC board

Ordinary PVC board is a plastic board made of polyvinyl chloride (PVC) resin through extrusion, calendering, injection molding and other processes. PVC boards are widely used in construction, advertising, furniture and other fields due to their excellent water resistance, corrosion resistance and easy processing.

Characteristics and applications of UV MDF boards

1. High gloss

The surface of UV MDF boards is cured by ultraviolet light, with high gloss, showing a mirror effect, making the surface of the board more beautiful.

2. Strong wear resistance

The UV coating has high hardness and good wear resistance, which can effectively resist scratches and wear in daily use.

3. Good environmental protection

UV coatings do not contain organic solvents, and no harmful substances will be released during the curing process, which meets environmental protection requirements.

4. Easy to clean

The surface of UV MDF boards is smooth, not easy to stain, and easy to clean and maintain daily.

5. Anti-ultraviolet

The UV coating has good anti-ultraviolet performance, which can effectively prevent fading and aging caused by sunlight.

6. Application scenarios

UV MDF boards are widely used in furniture manufacturing (cabinets, wardrobes, bookshelves, tables and chairs, etc.), interior decoration (walls, ceilings, door panels, etc.) and commercial displays (display cabinets, exhibition stands, etc.).

Characteristics and applications of ordinary PVC boards

1. Strong water resistance

PVC boards have excellent water resistance and will not deform, foam or peel even if immersed in water for a long time.

2. Corrosion resistance

PVC boards have excellent acid and alkali resistance and chemical corrosion resistance, and are suitable for special environments such as chemical plants and laboratories.

3. Easy processing

PVC boards have good processing performance and can be processed by cutting, bending, welding, etc. to meet the needs of different shapes and structures.

4. Lightweight

PVC boards are light and easy to install, which reduces the load on the building structure.

5. Good insulation performance

PVC boards have good electrical insulation performance and are widely used in the field of electrical insulation materials.

6. Application scenarios

PVC boards are widely used in building decoration (ceilings, wall panels, etc.), advertising production (display boards, signs, etc.), industrial materials (chemical anti-corrosion, cold storage partitions, etc.) and daily necessities (stationery, toys, etc.).

Comparison between UV MDF board and ordinary PVC board

1. Appearance and decorative effect

●UV MDF board: It has high gloss and mirror effect, high-end and beautiful appearance, suitable for high-end home and commercial decoration that pursues visual effects.

●Ordinary PVC board: The surface is smooth, but the gloss and decorative effect are not as good as UV MDF board, suitable for places with strong functionality and low decoration requirements.

2. Durability

●UV MDF board: Strong wear resistance, high surface hardness, good scratch resistance, suitable for furniture and decorative materials that are frequently contacted and used.

●Ordinary PVC board: Excellent water resistance and corrosion resistance, but weak wear resistance and scratch resistance, suitable for applications in humid and corrosive environments.

3. Environmental performance

●UV MDF board: UV coating is environmentally friendly, no harmful substances are released, in line with modern environmental protection standards, suitable for families and public places with high environmental protection requirements.

●Ordinary PVC board: PVC board may release harmful substances such as hydrogen chloride during production and use, and its environmental performance is relatively weak.

4. Maintenance

●UV MDF board: The surface is smooth and easy to clean. Just wipe it gently with a damp cloth to keep it clean.

●Ordinary PVC board: The surface is smooth and easy to clean, but the surface may be worn after long-term use, affecting the appearance.

5. Cost

●UV MDF board: Due to the complex production process and high material cost, the price is relatively high, which is suitable for decoration and furniture manufacturing with a higher budget.

●Ordinary PVC board: Low material cost, convenient processing, relatively low price, suitable for decoration and industrial applications with limited budget.

Actual case analysis

1. Home kitchen decoration

In the home kitchen decoration, a customer chose UV MDF board to make cabinet door panels, and another customer chose ordinary PVC board to make cabinets. After half a year of use, the cabinet door panels of UV MDF board are still as smooth as new, and there are no scratches and stains on the surface. Although the cabinets of PVC board have excellent water resistance, some small scratches appear on the surface, affecting the appearance.

2. Industrial factory

In the industrial factory, a company chose PVC board as anti-corrosion partition, and another company chose UV MDF board as wall decoration. After one year of use, the PVC board remained intact in a strong acid and alkali environment without corrosion or deformation. The UV MDF board performed well in a humid environment, but the surface showed slight fading in a strong acid and alkali environment.

Conclusion

UV MDF board and ordinary PVC board each have their own advantages and disadvantages and applicable scenarios. UV MDF board has an advantage in high-end home and commercial decoration with its high gloss, wear resistance and environmental protection performance, while ordinary PVC board performs well in industrial and functional applications with its water resistance, corrosion resistance and easy processing performance.