The advanced technology for surface treatment of decorative board - EB electron beam curing

2023-11-08 15:28

The advanced technology for surface treatment of decorative board - EB electron beam curing

What is EB electron beam curing?

EB electron beam refers to the electron beam generated by the acceleration of electrons in a high-voltage electric field. It is an energy carrier with ultra-high energy, capable of instantaneous solidification in 5 milliseconds, with an excellent curing degree of 100%, and without any harmful substance emissions. At the same time, EB electron beam curing technology, due to its ability to improve material performance and provide unparalleled physical and chemical properties, is currently the most efficient, high-quality, and clean coating and curing technology known. It was first applied to high-end fields such as aerospace and military industry, currency printing, and now it is applied to the sheet metal industry, comprehensively improving the functionality of the sheet metal and making people's home environment healthier and more environmentally friendly.

一: Principles of Electron Beam Curing

① Introduction to Electron Beam

An electron beam is released by direct or indirect heating of the cathode, and electrons are drawn out as a beam under the action of a high-voltage electrostatic field. Its characteristics are high energy, certain penetration, and precise control.

Electron beams use accelerated electrons to break chemical bonds and initiate chemical reactions, including crosslinking, grafting, curing, and sterilization. It can be applied in a wide range of fields, including automobiles, textiles, printing, and medical equipment, for improving material properties, increasing functionality, curing coatings and other materials, as well as disinfection and other applications.

② Electron beam curing

Electron beam curing technology is commonly referred to as "EB curing technology". It is currently the most efficient, high-quality, and cleanest coating curing technology known.

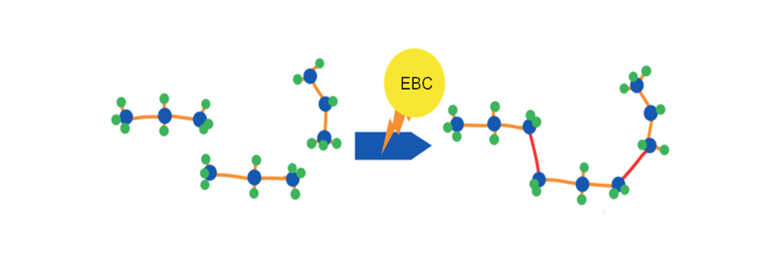

Electron beam is an energy carrier with ultra-high energy, which transfers its enormous energy to the surface of the coating, causing it to solidify 100% instantly, forming a three-dimensional cross-linking network, and thus obtaining high-quality coatings.

③ Characteristics and advantages of EB curing

Increase production

The electron beam has ultra-high energy, which can instantly 100% solidify the product, making it suitable for large-scale production, greatly shortening production time and effectively increasing output.

Energy conservation and environmental protection

Electron beam processing is different from traditional thermal and optical processing methods, as it can directly change the molecular structure to achieve energy-saving.

No color selection

The electron beam is color blind, and its penetration ability does not depend on optical clarity, but on material density. Therefore, electron beam curing has no limitations on the color of the coating, and its color saturation is extremely high.

Food grade

Electron beam curing does not require photoinitiators, as the accelerating electrons have sufficient energy to break chemical bonds and initiate reactions. Therefore, electron beams are widely used in food packaging.

Thoroughly cured

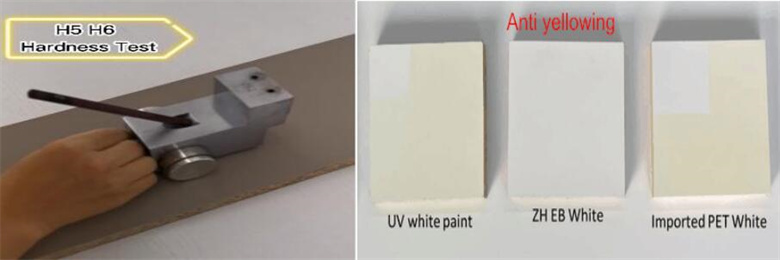

The electron beam has strong energy and the chemical reactions are carried out thoroughly, resulting in no residue or post reaction. Greatly improve the surface performance of the product, with outstanding resistance to yellowing.

Green Health

No volatile organic compound (VOC) emissions and environmental pollution during electron beam processing。

二: EB electron beam fixation in the decorative panel industry

In the process of board production, surface treatment is a very important part. After applying a specific coating to the substrate in the surface treatment step, a curing process is required to allow the coating to solidly adhere to the board in order to achieve its performance, reflect the appearance and texture of the board, and determine the final quality of the product. UV curing using ultraviolet light and EB electron beam curing are the main curing techniques.

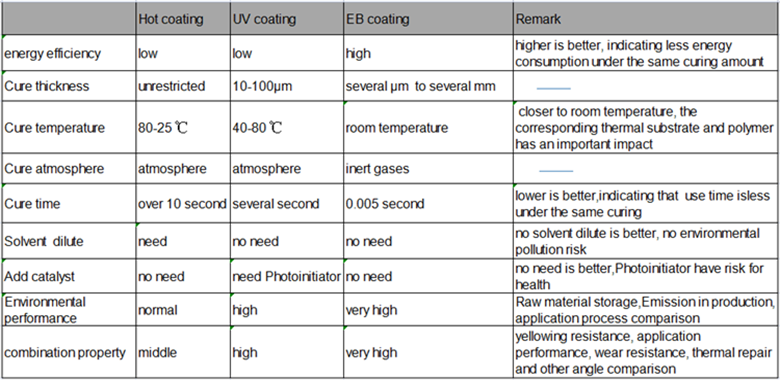

① EB electron beam curing compared to UV curing

The curing principle of EB electron beam is simply explained as using high-energy electron beams to directly act on molecules in the coating, thereby transforming the liquid coating into a solid state, thus achieving the curing process

UV curing utilizes ultraviolet radiation and photoinitiators to achieve the curing function

Comparison of Several Curing Methods

However, the penetration ability of ultraviolet rays in UV curing is limited, which can lead to residues deep in the coating. The residual photoinitiator may react with ultraviolet rays in daily use and cause yellowing.

The high-energy electron beam used for EB curing has extremely strong penetration, and deep coatings can also fully react. Moreover, since no additional solvents such as photoinitiators are required, there will be no environmentally friendly emissions such as VOC. Many food packaging and packaging also use EB technology, which further demonstrates the safety and environmental performance of this technology

② Characteristics of EB beam fixation applied to decorative panels

EB electron beam fixation forms a polymer three-dimensional network polymer through reaction, endowing the surface of the board with many characteristics:

(1) Corrosion resistance, mold resistance, and antibacterial properties: Excellent corrosion resistance, mold resistance, and antibacterial properties.

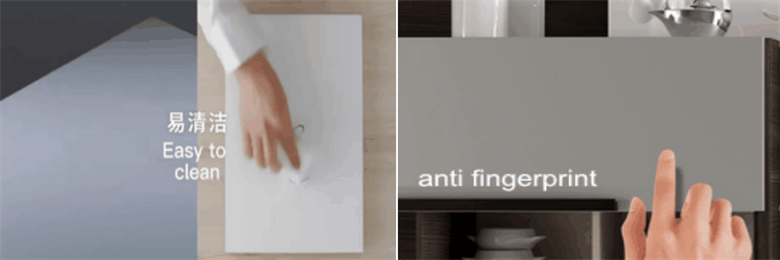

(2) : Stain resistant fingerprint: Oil and water stains in the kitchen can be easily wiped off, and fingerprints and fingerprints are not left behind

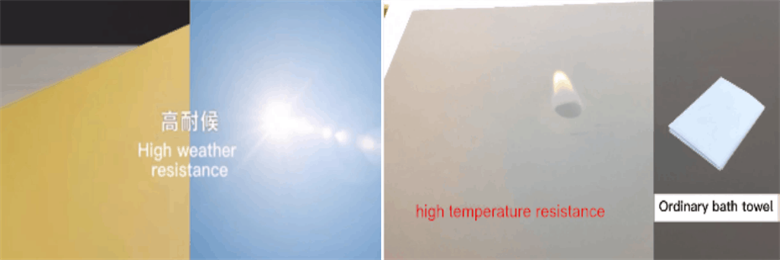

(3) Moisture and high temperature resistance: excellent waterproof performance, and no significant changes were observed on the surface of the alcohol ignited board during the experiment

(4) High hardness and durability: the cured surface has good strength and is resistant to collisions, and it reacts completely without yellowing after prolonged use

(5) Even minor scratches can be hot repaired: even if there are slight scratches, they can be hot repaired through hair dryers, irons, etc. The scratches can almost be restored to their original state

ZHI HUA group using the EB coating technology to process board surface,which with many design : pure color EB board, wood grain EB board, marble design EB board ,texture design EB board , which are with high gloss or super matte finish .

EB board size : 1220*2440*18MM, 1220*2745*18MM.

At the same time ZHI HUA group also USE EB coating to process polymer film: EB film with pure color EB board, wood grain EB board, marble design EB board ,texture design EB board , which are with high gloss or super matte finish .

EB film size : 1250*0.3MM for super matte ,1250*0.5MM for high gloss

EB sheet size : 1220*2440*0.8MM and 1220*2745*0.8MM

Welcome inquiry and collect swatches!