What are the Pros and Cons of UV MDF board compared with other boards?

2024-08-01 15:30

In modern home decoration and furniture manufacturing, the choice of board is crucial. UV MDF board has gradually become a popular material in the market due to its unique characteristics and diverse applications. However, faced with a variety of board choices, consumers often ask: What are the advantages and disadvantages of UV MDF board compared with other boards?

This article will analyze the advantages and disadvantages of UV MDF board in detail from the definition, characteristics, applications of UV MDF board and comparison with other common boards such as ordinary MDF board, HDF board, PVC board and solid wood board.

What is UV MDF board?

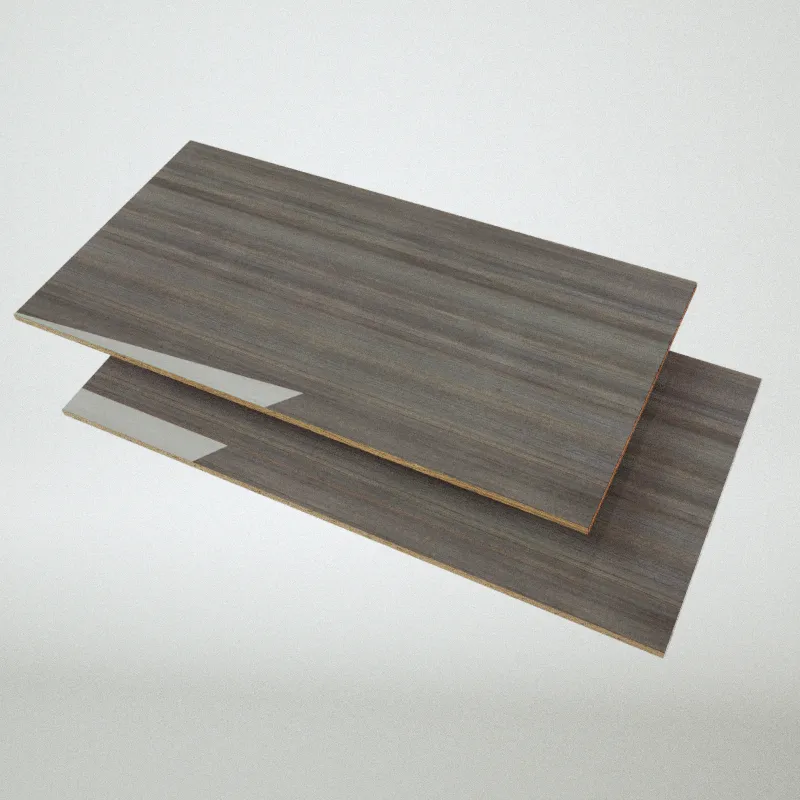

UV MDF board (ultraviolet light cured medium density fiberboard) is a board with ultraviolet light curing treatment on the surface of medium density fiberboard (MDF board). MDF board is made of wood fiber and synthetic resin pressed under high temperature and high pressure, while UV treatment is to apply a layer of UV coating on the surface of MDF board and quickly cure it by ultraviolet light irradiation.

What are the characteristics of UV MDF board?

● High gloss: UV coating makes the surface of the board present a mirror effect, with high-end visual effect.

● Strong wear resistance: UV coating has high hardness and can effectively resist scratches and wear.

●Good environmental protection: UV coatings do not contain organic solvents, and no harmful substances will be released during the curing process, which meets environmental protection requirements.

●Easy to clean: The surface is smooth, not easy to be stained, and daily cleaning and maintenance are convenient.

●UV resistance: It has good UV resistance and can prevent fading and aging caused by sunlight.

What are the application scenarios of UV MDF boards?

The application scenarios of UV MDF boards include: furniture manufacturing (cabinets, wardrobes, bookshelves, tables and chairs), interior decoration (walls, ceilings, door panels), commercial display (display cabinets, exhibition racks), etc.

1. Furniture manufacturing

UV MDF boards are widely used in the production of cabinets, wardrobes, bookshelves, tables and chairs and other furniture. Its high gloss and wear resistance make the furniture not only beautiful and generous, but also have a long service life.

2. Interior decoration

UV MDF boards are used for wall, ceiling, door panel and other decorations to meet the decoration needs of different styles. Its high gloss can create a high-end and fashionable indoor atmosphere.

3. Commercial display

UV MDF boards are used for display cabinets, exhibition racks, etc. in shopping malls, exhibitions and other places, which are both beautiful and practical. Its smooth surface and bright colors can enhance the display effect of goods.

Comparison of UV MDF board with other boards

1. UV MDF board vs. ordinary MDF board

● Glossiness: UV MDF board is treated with UV coating and has high gloss on the surface, while ordinary MDF board has a relatively rough surface and low gloss.

● Wear resistance: UV MDF board has strong wear resistance and can resist scratches and wear in daily use, while ordinary MDF board is more susceptible to wear.

● Environmental protection: UV MDF board's coating is environmentally friendly and harmless, while ordinary MDF board may use formaldehyde-containing adhesives during the production process, which has a certain impact on the environment and health.

● Application scenarios: UV MDF board is more suitable for places with high requirements for appearance and durability, while ordinary MDF board is suitable for inner structures and basic decoration with lower requirements.

2. UV MDF board vs. HDF board

● Density and hardness: HDF board (high-density fiberboard) has higher density and hardness and is suitable for load-bearing structures, while UV MDF board is suitable for surface decoration and furniture manufacturing.

●Glossiness: UV MDF board has better glossiness and decorative effect than HDF board, and HDF board is mostly used for structural applications that require high strength and durability.

●Application scenarios: HDF board is often used for floor substrates, laminate flooring, etc., while UV MDF board is more used for furniture and high-end interior decoration.

3. UV MDF board vs PVC board

●Water resistance: PVC board has excellent water resistance and is suitable for humid environments, while UV MDF board has certain water resistance, but not as good as PVC board.

●Decorative effect: UV MDF board has better glossiness and mirror effect than PVC board, and is more suitable for high-end decoration, while PVC board is suitable for functional places such as kitchens and bathrooms.

●Environmental protection: UV MDF board is more environmentally friendly, and PVC board may release harmful substances such as hydrogen chloride during production and use.

4. UV MDF board vs solid wood board

●Cost: UV MDF board has lower cost, while solid wood board has higher price.

●Appearance: Solid wood boards have natural wood grain and texture, suitable for high-end furniture and traditional decoration, while the high gloss and diversified design of UV MDF boards are more suitable for modern styles.

●Stability: UV MDF boards are not easy to deform or crack, while solid wood boards may deform when humidity and temperature change greatly.

●Environmental protection: UV MDF boards have better environmental protection performance, while solid wood boards need to use glue and paint during processing, which may have a certain impact on the environment.

What are the advantages and disadvantages of UV MDF boards?

Advantages of UV MDF boards:

●High gloss: UV MDF boards have a mirror effect and high-end appearance.

●Strong wear resistance: high surface hardness and strong scratch resistance.

●Good environmental protection: no harmful substances are released, meeting environmental protection requirements.

●Easy to clean: smooth surface, easy to clean and maintain.

●UV resistance: has good UV resistance, not easy to fade and age.

Disadvantages of UV MDF boards:

●General water resistance: UV MDF boards are not as water resistant as PVC boards, and are not suitable for long-term exposure to humid environments.

●Higher cost: Compared with ordinary MDF boards, UV MDF boards have higher production costs and are relatively expensive.

●Processing difficulty: The UV coating on the surface of UV MDF boards requires special attention during processing to avoid damaging the coating.

Conclusion

UV MDF boards have unique advantages in furniture manufacturing and interior decoration due to their high gloss, wear resistance and environmental protection. However, different boards have their own advantages and disadvantages and applicable scenarios. When choosing, consumers should make the most suitable choice based on specific usage needs and budgets, comprehensively consider the characteristics of the materials and application scenarios.