What is PET medium density fiberboard?

2024-07-26 15:30

In the modern home and building materials market, PET medium density fiberboard has gradually become a new material that has attracted much attention due to its excellent performance and environmental protection characteristics.

This article will introduce in detail the definition, production process, characteristics, application scenarios and competitive advantages of PET medium density fiberboard in the market, to help readers fully understand this emerging material.

What is PET medium density fiberboard?

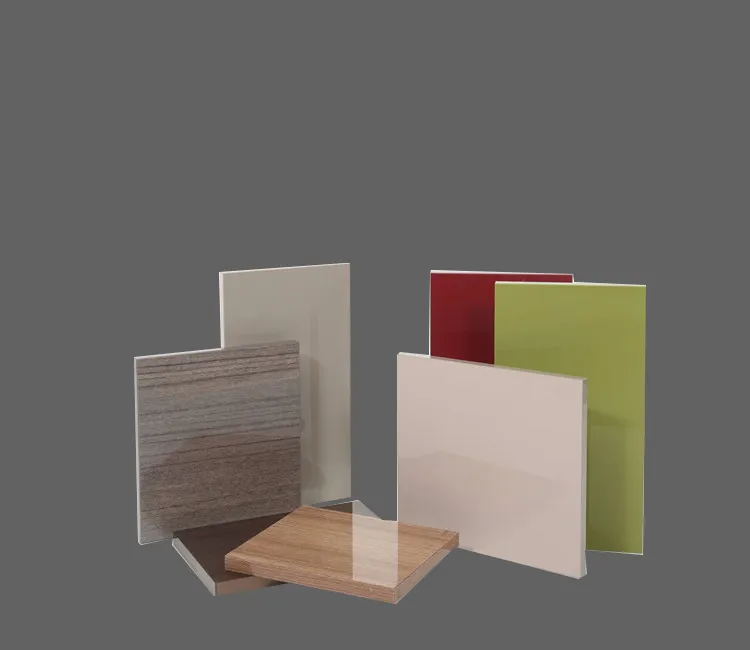

PET medium density fiberboard is a composite board made on the basis of traditional medium density fiberboard (MDF) combined with polyethylene terephthalate (PET) coating technology. MDF board is made by pressing wood fiber and synthetic resin under high temperature and high pressure, and has the advantages of uniform density and smooth surface. PET coating is an environmentally friendly polymer material with excellent wear resistance, UV resistance and good decorative effect.

How to produce PET medium density fiberboard?

1. Board substrate manufacturing

First, select high-quality wood fiber, and mix it with an appropriate amount of synthetic resin after processing through processes such as crushing, drying and grading. The mixture is pressed into a board substrate, namely MDF board, under high temperature and high pressure. This process ensures the uniform density and stable structure of the board.

2. PET coating treatment

A layer of PET coating is applied to the surface of the MDF board, and the coating thickness is usually 0.1-0.3 mm. The PET coating is cured by hot melt technology or UV curing technology to make it firmly attached to the surface of the MDF board. This process not only improves the wear resistance and UV resistance of the board, but also makes it rich in color and high gloss.

3. Surface treatment and molding

After the coating is cured, the surface of the board is polished to ensure that it is smooth and flat to achieve a high-end decorative effect. According to customer needs, the board can be processed into different sizes and shapes to meet the needs of various application scenarios.

What are the characteristics of PET medium density fiberboard?

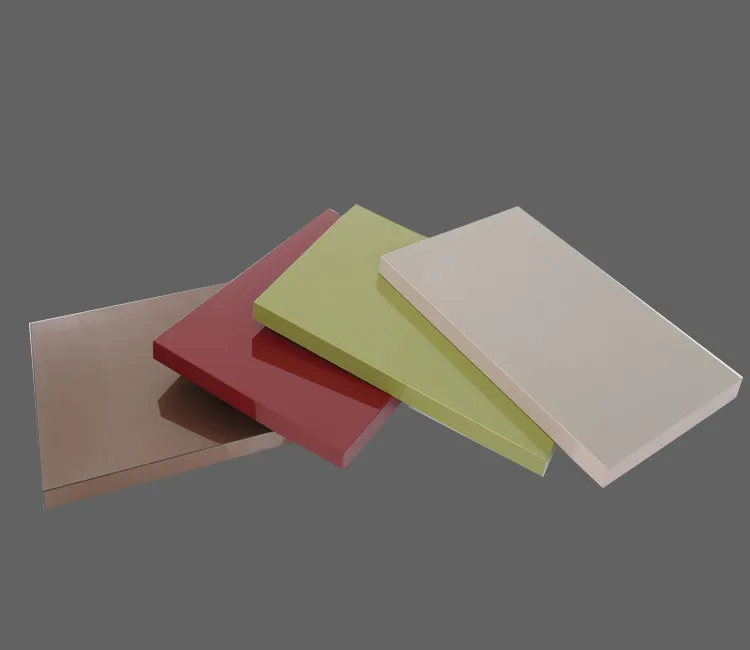

1. High gloss and aesthetics

The PET coating gives the board surface a mirror effect, high gloss, and outstanding visual effects. Rich color selection and texture design can meet the decoration needs of different styles.

2. Excellent wear resistance and durability

The PET coating has high hardness, excellent wear resistance and scratch resistance, and is suitable for high-frequency use places such as kitchens, office spaces, etc.

3. Good environmental performance

PET coating does not contain organic solvents, and will not release harmful substances during production and use, which meets environmental standards. In addition, environmentally friendly adhesives are also used in the production process of MDF boards to reduce formaldehyde release and ensure indoor air quality.

4. Easy to clean and maintain

PET medium-density fiberboard has a smooth surface, is not easy to stain, and is easy to clean and maintain. Daily cleaning only needs to be wiped with a damp cloth, and stubborn stains can be gently wiped with a neutral detergent.

5. Anti-ultraviolet and aging resistance

PET coating has good anti-ultraviolet performance, which can prevent fading and aging caused by sunlight, and keep the board beautiful for a long time.

What are the application scenarios of PET medium-density fiberboard?

1. Furniture manufacturing

PET medium-density fiberboard is widely used in the production of cabinets, wardrobes, bookshelves, tables and chairs and other furniture. Its high gloss and wear resistance make the furniture not only beautiful and generous, but also have a long service life.

2. Interior decoration

PET medium-density fiberboard is used for wall, ceiling, door panel and other decorations to meet the decoration needs of different styles. Its high glossiness can create a high-end and fashionable indoor atmosphere.

3. Commercial display

PET medium-density fiberboard is used for display cabinets and display racks in shopping malls, exhibitions and other places, which is both beautiful and practical. Its smooth surface and bright colors can enhance the display effect of goods.

4. Office space

In office space, PET medium-density fiberboard can be used to make furniture such as desks, partitions, and filing cabinets to enhance the overall beauty and comfort of the office environment.

Market competitive advantages of PET medium-density fiberboard

1. Environmental protection advantages

With the enhancement of environmental awareness, consumers' demand for environmentally friendly materials is increasing. The environmental protection performance of PET medium-density fiberboard gives it a significant advantage in market competition. No organic solvents are used in its production process, which reduces pollution to the environment and meets modern environmental protection standards.

2. Price advantage

Compared with solid wood boards, PET medium-density fiberboard has a lower cost and a more competitive price. Its high cost performance makes it an ideal choice for the mid-to-high-end market.

3. Performance advantages

The wear resistance, durability and easy cleaning characteristics of PET medium density fiberboard make it perform well in practical applications, reducing maintenance costs and troubles during use.

4. Aesthetic advantages

The high gloss and diverse decorative effects make PET medium density fiberboard stand out in home and commercial decoration, satisfying consumers' pursuit of high-quality life.

Conclusion

PET medium density fiberboard has become an ideal choice for modern home and commercial decoration due to its high gloss, wear resistance, environmental protection and diverse application scenarios.

In the future, with the continuous advancement of technology and changes in market demand, PET medium density fiberboard will continue to be optimized and upgraded to provide consumers with more high-quality choices.